What is Plastic Machining?

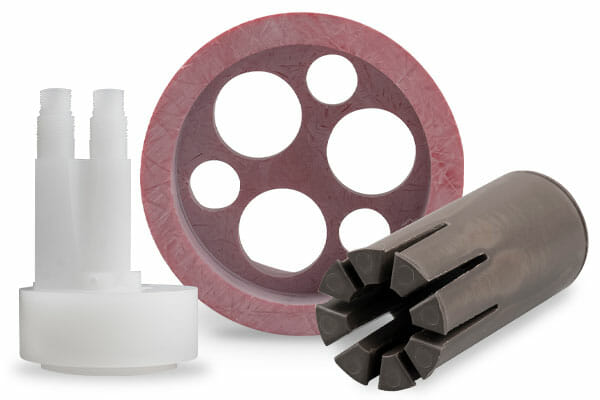

At Jaco Products, a top provider of plastic machining solutions, we specialize in advanced subtractive techniques to create custom plastic components that meet your exact specifications. Our proficiency covers the three primary machining methods—turning, milling, and drilling—guaranteeing exceptional quality for even the most detailed designs.

Turning: This process involves rotating the material using a chuck while a cutting tool shapes the workpiece to achieve the desired form. Precision lathes make turning ideal for crafting accurately shaped parts.

Drilling: In this method, the material is secured to a table, and a drill tool creates precise bores. Drilling offers versatility and can be performed on both lathes and mills, making it suitable for various applications.

Milling: A staple of any plastics machining company, milling fixes the material to a sliding table while cutting tools on a spindle shape complex forms. This technique is essential for producing intricate and high-precision plastic parts.

Looking for a Reliable Plastic Machining Company?

Jaco puts quality, experience, and commitment into every phase of the machining process. We maintain state-of-the-art machining capabilities and ensure our equipment undergoes rigid quality inspections. We take pride in our attention to detail when providing CNC plastic machining because it means a quick and efficient turnaround for you. Our competitive prices and on-time delivery of your precision machined components help improve your business and streamline your operations.

We understand how important it is to find a company that is capable of giving you what you need on time. We commit to quality parts and we get those parts to you by the deadline and at an affordable price.

Why Work With a Plastic Machining Manufacturer?

Jaco Products is proud to be a leading plastic machining manufacturer in Ohio. We are a one-stop shop for custom injection molding services and precision plastic machining. But why should you choose Jaco as the plastic machining manufacturer for your precision machined plastic parts? Simply, we have the highest quality materials and the most efficient processes.

We take efficiency seriously at Jaco. We don’t like to waste any product. Machining plastic parts requires CNC technology for exact cuts and preventing mistakes. This guarantees there is no material wasted and less material is used overall. Our clients benefit from this process because the machining plastic process is fast and efficient, so turnaround times for their machined parts are exceptional.

Another reason to choose a plastic machining manufacturer like Jaco is durability. Thanks to our numerous plastic fabrication processes, we can manipulate plastic components into any machined plastic part that you need. When you need reliable parts and fast turnaround times, choose Jaco Products.

Experts in Machining Difficult Materials

With Jaco Products, our experts have the ability to machine materials that most shops won’t touch. Reach out to us for a quote on any plastic materials you need machined.

Machining Delrin

Delrin plastic has a wide variety of uses, from gears to conveyor system parts. Delrin is a durable plastic that is resistant to moisture and chemicals. But Delrin doesn’t respond well to adhesives, which make bonding difficult. Delrin is a flammable plastic that can become deformed during machining if the heat is too high.

Machining Delrin, a thermoplastic, is different from machining thermoset plastics. Thermoplastics melt when heat is applied and thermosets remain set once they are formed. These specific intricacies must be understood to machine Delrin parts. Jaco Products has the knowledge and expertise to machine Delrin into the product you need.

Ultem Machining

Ultem plastic is a semi-transparent, high-strength plastic that can operate in high temperature environments. Some other advantages of Ultem are that it is conductive and food contact acceptable. Ultem processing costs are high, there are limited color options, and it requires high processing temperatures.

Peek Machining

PEEK plastic, or polyetheretherketone, is a semi-crystalline thermoplastic. It has low moisture intake, strength across various temperatures, and high chemical resistance. PEEK is expensive and not very resistant to UV light.

Nylon Machining

Jaco’s vast experience in nylon machining creates the ability to offer competitive pricing for CNC machined nylon parts. Jaco has the best plastic machining processes to speed up the traditional setup of machining plastic. Jaco’s methods decrease the number of setups by a significant amount.

Nylon machining brings a wide range of benefits and is lightweight, wear and vibration-resistant, and has a high tensile strength. If you are replacing an older product or creating a product from scratch, our nylon machining will bring you the most durable product possible and stay within your budget.

Precision CNC Plastic Machining at Jaco Products

Our CNC Plastic Machining capabilities allow us to handle orders of any size, and we guarantee you will be happy with your product. We also offer assistance with prototyping and research, as well as development of new product design. Our goal is to get your product to you as quickly and affordably as possible. This means we use the most efficient method possible each step of the machining process. From product design to manufacturing and delivery, you can count on us to get it done on time and for an affordable price. We welcome complex projects.

Custom Plastic Machining To Suit Your Needs

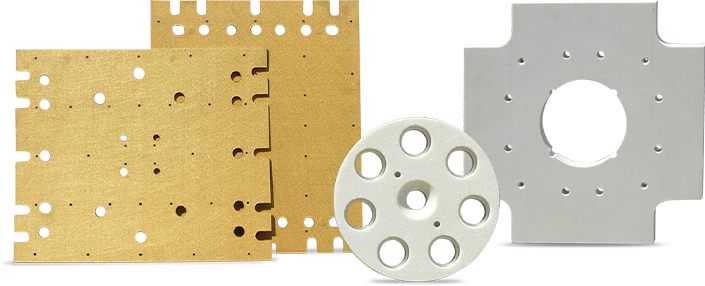

The goal of a custom plastics machining manufacturer’s process is to deliver products that match your specifications, and we know that every industry and application has unique requirements. That’s why we provide a package for both pure and mixed-composition molds, which can be customized according to your specific size or shape.

Traditional machine shops aren’t equipped with the right equipment and expertise of a plastic machinist. Outsource your plastic machining work to Jaco to get the right parts, on-time, and to the exact part specifications.

If someone has said no to your project because it’s too complex, chances are we can do it. Contact Jaco today to learn more. Give us a call at 440-632-5800 fax 440.632.0012.

Plastic Materials We Work With

Jaco specializes in the machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

- Udel

- UHMWPE

- Acrylic

- Ultem

Jaco Offers the Following Plastic Manufacturing Services:

High Quality Plastic Machining Services

Our quality control department ensures each and every product that leaves through our door is to specifications. We use the most advanced techniques and machinery to create the best possible product. We guarantee your part will meet your expectations. It’s why people trust us to create complex parts that others cannot.

We know how important it is to you to get a quality product that meets your needs. We do all we can to help you do this. If you would like to learn more about Jaco’s plastic machining services, give us a call 440-632-5800 • fax 440.632.0012.

CNC Plastic Machining

Computerized Numerical Control (CNC) machining is a precise and efficient automated plastic fabrication method. This process allows for high-volume production of complex plastic parts with incredible ease. Here at Jaco, we combine our expertise with thermoplastics and thermoset materials with state-of-the-art CNC machinery. We can perform a full range of processes including routing, milling, turning, and 5-axis machining with high-precision tolerances of .0001″.

We are always looking for ways to improve our plastic fabrication equipment and technology. As a result, we are always equipped to meet even the highest tolerance requirements while offering a quick turnaround for projects of any volume.

Plastic Injection Molding

Plastic injection molding is another common technique for creating plastic components. The injection molding process consists of reshaping melted plastic materials by forcing them into a cavity and applying pressure. The mold cavity shapes the plastic into the desired configuration, and once the plastic cools we can remove the finished part.

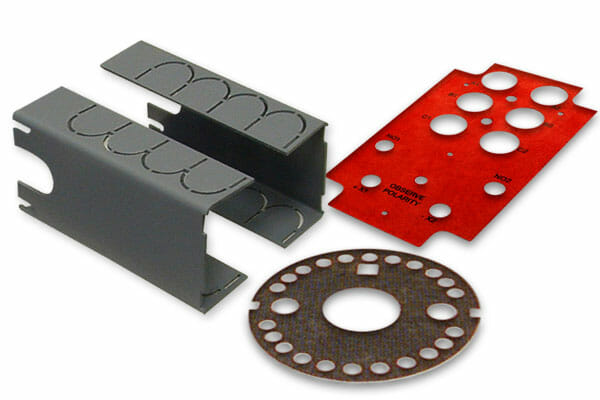

Stamping and Die Cutting

Plastic stamping and die-cutting are exceptionally efficient machining methods. In fact, these processes can minimize overall material costs while increasing production rates and improving dimensional uniformity. Many electrical insulation companies depend on Jaco for our stamping and die-cutting services to produce reliable products.

Mold and Platen Insulation

Mold and platen insulation is another specialty of Jaco Products. These insulation products can control how heat transfers to production presses, so they can minimize energy usage and enhance your processing variables. Whether you need mold or platen insulation or thermal insulation board, we offer high-quality products in 17 separate materials, so we can meet the requirements of your unique application.

Plastic Materials Distribution

Creating high-quality plastic components requires high-quality materials. Here at Jaco, we use only the finest available materials in the production of all of our plastic parts. We carry a full range of thermoset and thermoplastic materials, so you can find the best fit for your project. If you are unsure of what material is best for your application, our technical staff is ready to provide professional recommendations based on your application requirements.

Learn more about our plastic material distribution services.

5-Axis CNC Plastic

If you are looking for a complex part to be machined, 5-axis CNC plastic machining from Jaco will get the job done. 5-axis CNC plastic machining creates consistency for your exact parts specifications. Allow Jaco Products to review your plastic parts to determine how to reduce your costs and increase the quality of your parts.

Plastic Machining Solutions

The challenges faced with plastic machining mean that you need a plastic machining company that is willing to take on a a challenge. With Jaco Products, we use our extensive expertise to create solutions for your plastic machining challenges. We use innovative techniques in design and plastic matching to combine precision processes and quick production at a reasonable price.

The challenges faced with plastic machining mean that you need a plastic machining company that is willing to take on a a challenge. With Jaco Products, we use our extensive expertise to create solutions for your plastic machining challenges. We use innovative techniques in design and plastic matching to combine precision processes and quick production at a reasonable price.

Plastic Machining Manufacturer

There are many precision plastic machining manufacturers across the globe. To find the best plastic machining manufacturer for a project, it’s crucial to define the project specifications and determine how well the prospective plastic manufacturer will execute the ideas.

Jaco Products is an experienced plastic manufacturer with a large portfolio of plastic services to manufacturer unique products for our clients. We consider our client’s budget, offer various applications for our plastic parts, and strive to develop long-term partnerships. Jaco collaborates with more than thirteen different plastic mediums to create top-notch products that deliver the best results.

Our extensive experience with plastic machining manufacturing allows us to develop successful plastic components to help improve and grow our client’s businesses. If you are ready to begin your next project or have questions about our services, contact us today to learn more about Jaco Products.