Working with Delrin in Plastic Applications | Delrin Machinability and Properties

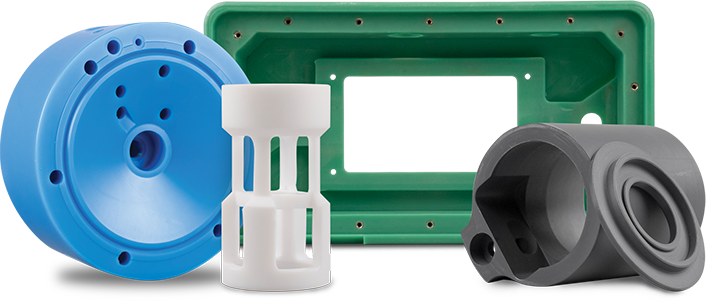

Delrin is a highly adaptable plastic material, widely used in various applications and processes, including CNC Delrin machining and plastic die cutting. Officially known as Delrin acetal homopolymer (Polyoxymethylene POM), it is a go-to choice in industrial environments for producing components like wear strips, pistons, valves, rollers, and more. Often selected as a metal substitute, Delrin stands out for its remarkable attributes such as high tensile strength, low friction, and outstanding wear resistance, making it an ideal choice for numerous applications.

The Delrin machining tolerances are up to par with those of popular metals, despite this being a plastic part. Delrin also has high density and a low moisture absorption rate. Plus, it’s resistant to solvents and neutral chemicals, which makes working with Delrin popular in industrial and machining applications. The Delrin machinability and high tolerances means that it creates parts, like the Delin ring, that can withstand demanding applications. Let’s take a look at some of the top traits of Delrin that make it a popular material.

Delrin Machinability | Understanding Delrin Machining Tolerances

When working with Delrin, particularly in a stressful application, you have to be aware of properties such as strength and heat deflection.

In general, the tensile strength of Delrin is between 6,000-22,000 PSI. Tensile strength is simply the resistance of a material to breaking under tension, which means that the higher the number, the more durable the material. If you are working with Delrin for a specific, high-stress application, you will need Delrin with high tensile strength.

Another important aspect of Delrin machining tolerances is the impact strength, which is also called impact toughness. Impact strength is the amount of energy a material can withstand when a load is suddenly applied to it. When machining Delrin for high-intensity applications, this number is essential to establish. Generally, the impact strength of Delrin is between .75-2ft-lb/in. For specific questions about Delrin machinability and Delrin machining properties, the experts at Jaco can provide specific numbers.

Other important and likeable qualities of Delrin include:

- Chemical resistance

- High fatigue endurance

- Quality Delrin Machinability

- Low moisture absorption

- Good wear properties (Delrin ring, for example, is popular because of its longevity)

Contact Jaco to learn more about our capabilities for Delrin machining and Delrin plastic injection molding.

Why Choose Delrin Machining for Your Next Part?

Delrin machining is ideal for a variety of applications. Jaco has immense experience working with Delrin plastic, so we understand the benefits of utilizing this durable material for your projects.

Machined Delrin, sometimes called acetal, provides a variety of benefits. It is easy to machine and fabricate with low, consistent internal stress, but it also produces a quality product that is tough to wear out. It undergoes little dimensional change during machining and use. Delrin is wear and impact resistant, so it is ideal for a number of industrial and mechanical industries.

Delrin Machining Offers Many Advantages

In addition to its strength and durability, machined Delrin is also moisture resistant, which makes it ideal for use in wet environments. It is also resistant to hydrocarbons, solvents, and neutral chemicals, and offers stiffness, dimensional stability, and resilience, making it ideal for a variety of uses, including:

In addition to its strength and durability, machined Delrin is also moisture resistant, which makes it ideal for use in wet environments. It is also resistant to hydrocarbons, solvents, and neutral chemicals, and offers stiffness, dimensional stability, and resilience, making it ideal for a variety of uses, including:

- Pump components

- Pistons and valves

- Rollers

- Fittings

- Manifolds

- Food product forming dies

- Timing screws

- Wear strips

- Electrical insulator parts

- Gears, bearings, and bushings

People from a variety of industries rely on Jaco to get the exact part they need. Jaco offers expert assistance designing a prototype and can recommend the proper material, no matter the end result you need. As a result, companies in many industries rely on Jaco to make the parts they need. In many cases, Delrin is the most effective material. However, nylon machining is a great alternative. People in the automotive, food processing, fluid handling, material handling equipment, and electronics manufacturing industries all use Delrin for its reliable properties. Those in need of Delrin machining can rely on Jaco.

Jaco Services

CNC Delrin Machining

CNC machining offers unmatched versatility in plastics manufacturing. It can develop products for many industries and applications. CNC stands for Computerized Numerical Control, which means computerized devices control many of the plastics manufacturing processes. We also apply our experience with thermoset and thermoplastic materials to further improve the CNC process. Our CNC machining capabilities include 5-axis machining, routing, milling and turning with precision tolerances of .0001″. Furthermore, we work to consistently improve both our machinery and manufacturing methods. Thus, we are increasingly efficient at producing small to large volume runs with high tolerances.

Plastic Injection Molding

Injection molding is a shape-forming process, involving the melting, squeezing, and forcing of plastic materials into a desired shape or configuration. Once we achieve the proper shape, we cool the rubber, release the mold and restart the cycle. In addition, this method is efficient in producing solid objects.

Mold & Platen Insulation

Implementing high-performance thermal insulation is an effective way to significantly reduce energy consumption while improving processing efficiency. In addition to plastic components, Jaco is a top supplier of thermal insulation board, mold insulation, and platen insulation. Our insulation products also come in 17 different materials.

Stamping & Die Cutting

Jaco is a leading provider of stamping and die-cutting services to the electrical insulation industry. Thus, we can manufacture complicated parts with higher tolerance requirements quickly and reliably. Furthermore, this method is ideal for the reduction of material costs and the improvement of production rates and component uniformity.

Your Satisfaction is Our Aim | Delrin Machining

At Jaco, we understand your priorities and make them our own. We know you want a reliable product, efficient manufacturing, and competitive pricing, so we never sacrifice quality. Our team will work with you to design a prototype to suit your expectations and your budget.

And if you already have a prototype, we can take the manufacturing process from there. We’ll source the best materials and provide a thorough inspection of the end result before you sign off.

We want to work for you. Contact Jaco for more information or to discuss your current needs for Delrin machining.

Delrin Machinability Versus Other Plastics

Working with Delrin might mean the decision to not work with other plastics. While there are plenty of strong and durable plastics available, Delrin stands out for its high impact resistance, chemical resistance, and high tensile strength. In fact, the Delrin machining tolerances even outperform that of certain metals.

That means parts can be created to be even stronger using this type of plastic, as opposed to a metal. Delrin ring and other parts are used in many facets of manufacturing, which demonstrates how working with Delrin extends across industries. From the automotive industry, to food processing, to electronics, manufacturers love working with Delrin and machining Delrin thanks to its strength, resistance, and longevity.

Working with Delrin | Jaco Products

If your team is interested in working with Delrin, Jaco Products can help. With each project we complete, we prioritize attention to detail, precision, and accuracy. Jaco will engineer parts that other companies won’t even quote, because we don’t shy away from a challenge.

As mentioned, Delrin machinability makes it a popular choice of a plastic material. But if your company hasn’t used Delrin ring before, or if you are new to working with Delrin, our team can explain all of the nuances of this process. We are eager to help guide you through our process, answer specific questions, and serve as your go-to resource for plastic machining, plastic molding, and Delrin machining.

Contact the team at Jaco Products today to get started in working with Delrin.

Other Plastic Materials We Work With

Jaco specializes in the machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

- Udel

- UHMWPE

- Acrylic

- Ultem