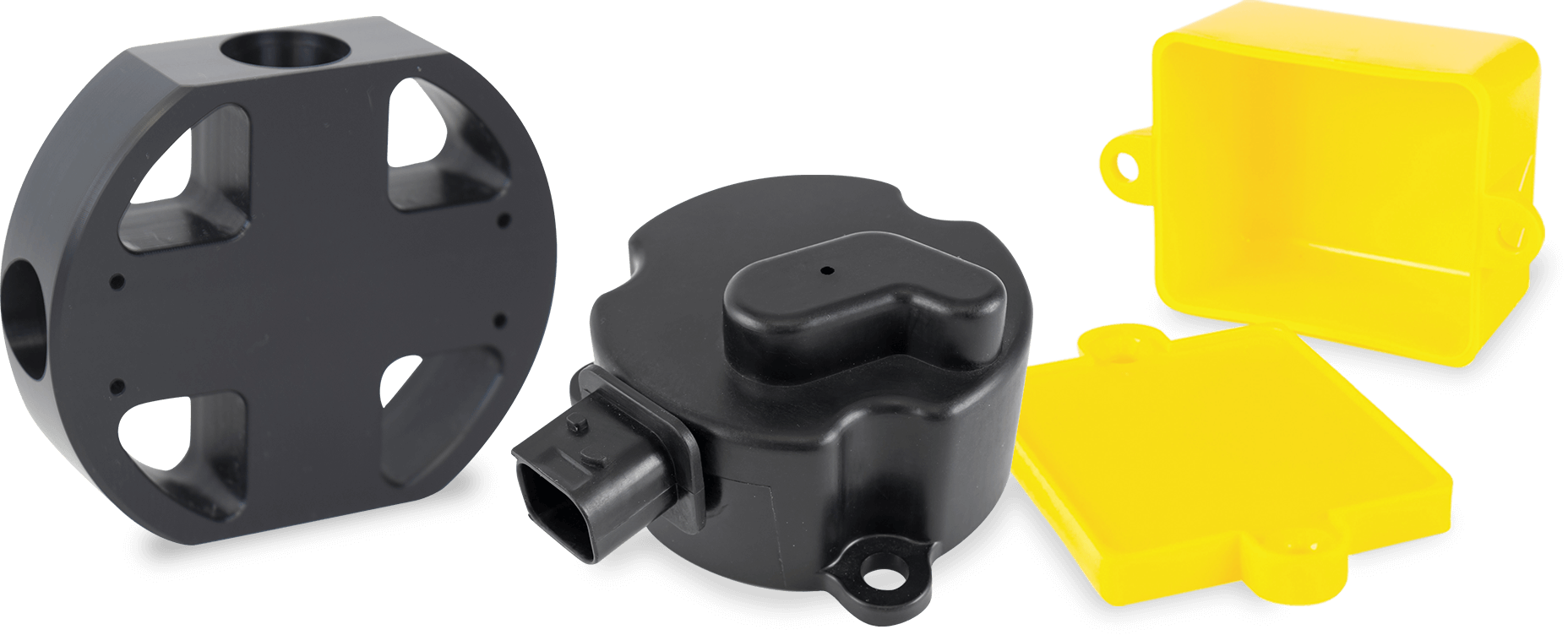

This LED light ring is a mature delrin plastic part that was brought in by a customer looking to lower overall costs for the component. The part required a ± 0.001″ close on the ID, OD and distance between centerlines. The previous plastics machine shop that produced the part had a difficult time achieving these tolerances with machining delrin. However, with our experience in plastic machining particularly machining delrin, Jaco was capable of manufacturing the LED light ring at a reduced cost.

The part is applicable in high-end inspection equipment featuring a camera taking high-speed photography for quality control. The exact hole positioning and size tolerances was critical to the performance of the inspection equipment.

By applying advanced 5-axis CNC machining, Jaco reduced the plastic part cost while holding tolerances that other machine shops couldn’t achieve. Contact Jaco to learn more about our capabilities for Delrin machining and Delrin plastic injection molding.

Using Delrin in Precision Manufacturing

Machining Delrin Offers Many Advantages

In addition to its initial strength and performance, delrin provides incredible moisture resistance. As a result, it is ideal for applications in wetter environments. Additionally, delrin offers resistance to hydrocarbons, solvents and neutral chemicals as well as superior dimensional stability and resilience. Delrin offers optimal performance in the following applications:

- Pump components

- Pistons and valves

- Rollers

- Fittings

- Manifolds

- Food product forming dies

- Timing screws

- Wear strips

- Electrical insulator parts

- Gears, bearings, and bushings

- And More!

CNC Machining Delrin and Plastic

Jaco CNC plastic machining is an effective manufacturing method for the development of products for many different applications. The CNC (Computerized Numerican Control) process utilizes various computerized devices to complete many manufacturing tasks. We also apply our immense experience with thermoset and thermoplastic materials to further increase the efficacy of CNC machining.

Our machining capabilities include 5-axis machining, milling, routing and turning with tolerances of .0001″. We regularly improve our machinery, technology and manufacturing methods, so we can more easily produce parts with high tolerance requirements.

Other Plastic Materials We Work With

Jaco specializes in the machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

- Udel

- UHMWPE

- Acrylic

- Ultem

Why Choose Jaco Over Other Plastic Manufacturing Companies?

Jaco is a leading plastic manufacturing company, so we have the ability to offer many unique advantages:

- Advanced quality control processes.

- Project assistance from prototyping to the final stages of manufacturing.

- Advanced CNC manufacturing equipment for the fabrication of high-quality products with competitive pricing.

- Vendor managed inventory systems.

- Long-term professional relationships.

- Custom packaging options.

- Dedication to complete customer satisfaction for every project.

Jaco Products offers superior service variety and higher quality materials resources than our competitors. We are also more capable of completing challenging plastic manufacturing projects with even the more strict application requirements. Additionally, with an innovative manufacturing process, we can deliver custom solutions to fulfill the requirements of any application. If you’re looking for a reputable plastics manufacturer, you can depend on Jaco to get the job done.

Contact Jaco to learn more about our critical part machining delrin and expertise in plastic fabrication and how we can lower your cost on your complex machined plastics.