What is Delrin?

Delrin®, a leading polyoxymethylene (POM) material developed by DuPont, is a high-performance engineering thermoplastic valued for its excellent stiffness, dimensional stability, hardness, and strength. Alongside Delrin®, other well-known POM brands like Kocetal, Ultraform, and Celcon are widely used across various industrial and engineering applications due to their reliable mechanical properties and durability.

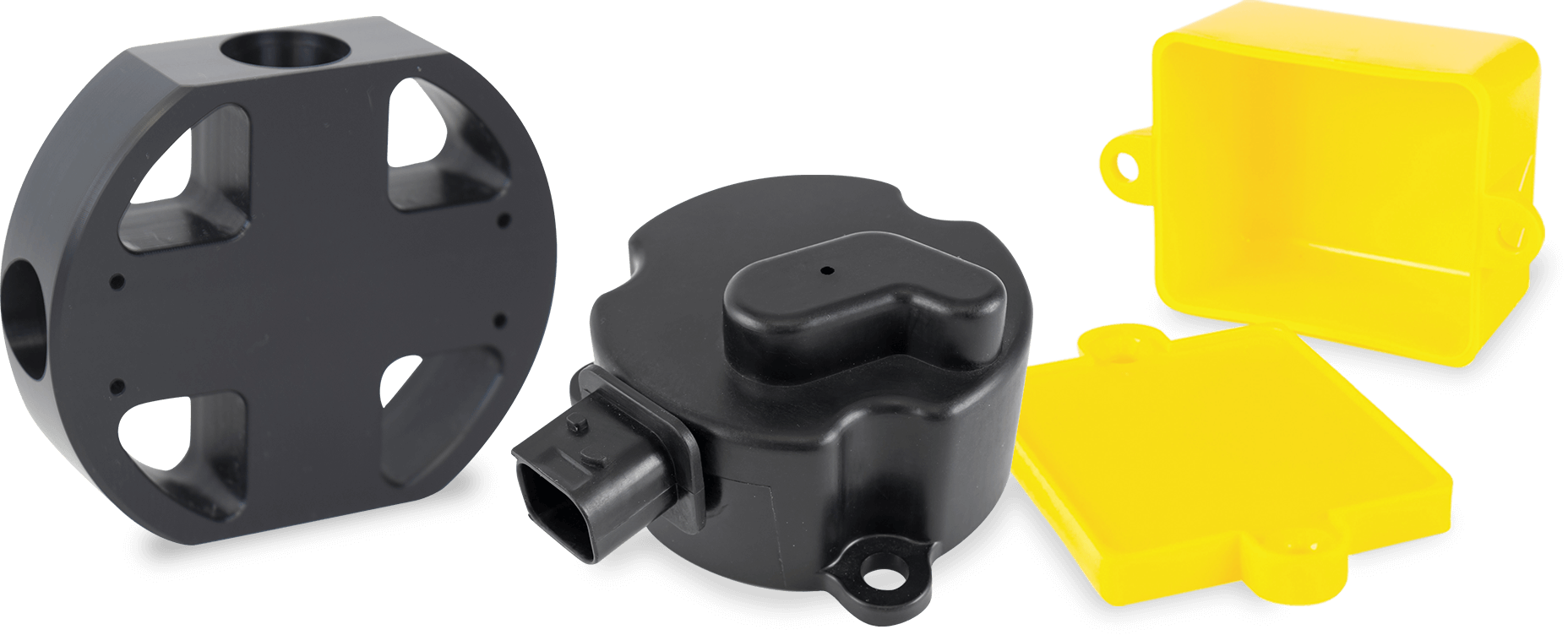

While Delrin is commonly supplied as sheets or extruded rods for machining, it is also widely utilized in injection molding Delrin processes. In its granulated form, Delrin is ideal for producing durable, precise components through injection molding and plastic extrusion. However, for intricate designs with undercuts or internal shapes that cannot be achieved via injection molding, plastic machining remains the preferred solution.

Contact Jaco to learn more about our capabilities in Delrin machining and Delrin plastic injection molding.

Leading companies across the globe use Delrin for high-load mechanical applications such as gears, safety restraints, door systems, conveyor belts, healthcare delivery devices, and other products and parts for demanding applications. It combines low-friction and high-wear resistance with the high strength and stiffness. It provides a wide operating temperature range (-40 °C to 120 °C) and good colorability. Delrin also mates well with metals and other polymers and offers excellent dimensional stability in high precision molding.

Delrin offers higher tensile strength, creep and fatigue resistance, and significantly higher impact resistance. The combination of these excellent mechanical properties in a single material allows for thinner, lighter-weight parts and shorter molding cycles with the potential for significant cost reductions.

Advantages of Machined Delrin

Delrin provides incredible moisture resistance. As a result, it is ideal for applications in wetter environments. Its resistance to hydrocarbons, solvents and neutral chemicals as well as superior dimensional stability and resilience.

Machined Delrin Part Advantages

Delrin Applications

Delrin VS Plastic | What is Delrin Machining?

Customers will often confuse Delrin with acetal. Acetal is the common name for Polyoxymethylene (POM), which simply refers to a group of thermoplastics. While Delrin plastic is a type of acetal, acetal is not a type of Delrin. Rather, Delrin fits under the blanket category of acetal materials. Delrin plastic material is the common name for homopolymer acetal.

So what about other forms of acetal? How does the Delrin insulator compare? Let’s take a look at copolymer acetal, which is used commonly in electronics and automotive industries. Copolymer shares several Delrin material properties, as it has high strength and toughness, as well as high dimensional stability. However, Delrin plastic is known to have even more strength and resistance compared to copolymer.

Delrin properties that separate further from copolymer also include its low moisture absorption and its greater stiffness. Delrin plastic also has a lower coefficient of friction, which is just the ratio between the force needed to move one surface horizontally over another, and the pressure between the two surfaces.

Just because Delrin mechanical properties differ from other plastics, it doesn’t always mean that it is the right choice for your specific application. Delrin insulator, Delrin bushings, and other parts are widely used in industrial applications. However, if the application does not need this level of strength, this may be the wrong plastic material for you. The best way to determine the best material is to talk to the Delrin material suppliers at Jaco Products. Our team has decades of experience working with products like Delrin, and other specialized plastics, to help our customers get the results they are seeking.

What Does it Take to Machine Delrin Parts? | Delrin Mechanical Properties

When machining Delrin parts, it’s important to note that Delrin is a thermoplastic. A thermoplastic is essentially a plastic polymer that becomes pliable at a certain temperature, and then solidifies upon cooling. Common thermoplastics include acrylic and polyester, though Delrin plastic is also a thermoplastic.

The process of machining Delrin plastic is different from machining a thermoset. A thermoset is different from a thermoplastic because it remains “set” once formed, while thermoplastics melt in the heat. For that reason, it helps to know the Delrin material temperature range when working with this material.

So what does it take to machine Delrin plastic? As mentioned, Delrin plastic material is a popular choice in molding and plastics industries because it’s strong, stable, and easy to work with. For applications that need tight or specific tolerances, these Delrin material properties are extremely important. In order to machine Delrin parts, keep in mind that Delrin is sensitive to heat at or about 250F. If you aren’t aware of the Delrin temperature range, you risk deforming the plastic before it reaches its final application.

Here at Jaco, our experts understand the intricacies of machining Delrin parts and can expertly work with Delrin plastic material to meet your requirements.

In order to cool Delrin bushings, consider air-based coolants. This will achieve close tolerances as well as provide a smooth finish. With the right coolant, you can extend the life of Delrin plastic parts.

Another key aspect of machining Delrin plastic material is to avoid any contamination. There are certain demanding industries, like medicine and aerospace, that need Delrin parts that won’t fail. Because of this, the highest level of sanitation needs to be established and maintained by Delrin material suppliers. Jaco Products understands the level of precision and accuracy required to safely process Delrin plastic material, and deliver products to our customers that meet exact specifications. Where other plastic processing companies may shy away from machining Delrin parts, we are eager to take on even the most complex projects.

Jaco Machined Delrin Services

We specialize in engineered materials such as injection molded Delrin and machined Delrin.

Jaco CNC Delrin machining is an effective manufacturing method for the development of products for many different applications. The CNC (Computerized Numerical Control) process utilizes various devices to complete many manufacturing tasks. We also apply our extensive experience with thermoset and thermoplastic materials to further increase the efficacy of CNC Delrin machining.

Our Delrin machining capabilities include 5-axis machining, milling, routing and turning with tolerances of .0001″. We regularly improve our machinery, technology and manufacturing methods, so we can more easily produce parts with high tolerance requirements.

Plastic Materials We Work With

Jaco specializes in the machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

- Udel

- UHMWPE

- Acrylic

- Ultem

Why Choose Jaco Over Other Plastic Manufacturing Companies?

Jaco Products offers superior service variety and higher quality materials resources than our competitors. We are also more capable of completing challenging plastic manufacturing projects with even the more strict application requirements. Additionally, with an innovative manufacturing process, we can deliver custom solutions to fulfill the requirements of any application. If you’re looking for a reputable plastics manufacturer, you can depend on Jaco to get the job done.