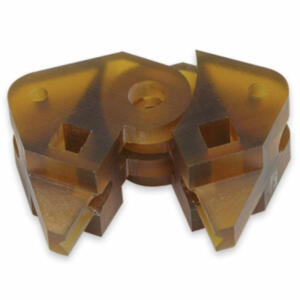

Jaco Products stands at the forefront of the industry, specializing in the production of complex plastic parts that other manufacturers often “no quote.” Central to Jaco’s success is its mastery of advanced molding techniques such as injection molding, compression molding, and transfer molding. With these capabilities, Jaco consistently delivers precision-engineered components, ensuring unmatched quality and consistency in every part they produce.

From intricate geometries to tight tolerances, Jaco thrives on the challenge of producing parts that exceed the expectations of its customers. Whether it’s a custom prototype or a high-volume production run, Jaco’s comprehensive suite of capabilities enables it to deliver solutions tailored to the unique needs of each client.

Custom Plastic Parts

Whatever the shape, size, quantity, or material needed for your next plastics project, Jaco Products can help. We fabricate plastics that other companies won’t touch, and our 5-axis equipment allows us to cut shapes that others cannot.

Design your part

Custom plastic injection molding begins with the design of your part. We collaborate with our customers on producing designs that are both effective and cost-efficient to make. Small tweaks at the design stage can make all the difference when the part is manufactured. Help us to help you by bringing your design to us in the early stages so we can make recommendations.

Right first time

Designing molds is expensive and time consuming, so getting it right first time is important. Once the mold is set up to your specifications, the molding process is quick and efficient, and money can be saved with an intelligent approach to mold design at the beginning of a project.

A combined approach

After the initial setup, plastic injection molding is a quick, low-waste process. At Jaco we use a combination of injection molding and machining to fabricate complex and difficult-to-manufacture parts. Our operation is set up to machine complicated plastic shapes that other shops won’t touch.

Reduce costs

Our state-of-the-art machinery can rout, mill, and turn to extremely low tolerances. CNC machining cuts down on labor costs and significantly reduces the overall cost of producing a part.

Does Your Company Have CNC Plastic Machining Needs?

Get your plastic parts made no matter how complex. With state-of-the-art equipment and fundamental knowledge of plastic machining, Jaco is your manufactured plastics solution.

Machining Different Plastics

Delrin

Delrin is supplied in sheets and bars for the purpose of milling and turning and supplied in granular form for melting and placing in molds. It has excellent dimensional stability and is easy to cut to very low tolerances. It is high strength and is resistant to chemicals. Delrin is an excellent dielectric. It can be difficult to use adhesives with Delrin, however, but in our experience, it is possible to manufacture complete parts from a single mold and by using an intelligent approach to CNC machining the material.

Ultem

Ultem is a high-performance thermoplastic that has excellent heat and flame resistance. It is supplied in the form of rods, sheets, tube, or film. Glass-reinforced Ultem requires coolant to machine, as well as hardened metal tooling. Ultem is a high-performance plastic that is stiff, strong, and relatively easy to machine. Some grades of Ultem are more difficult to machine because of their stiffness—specifically glass reinforced Ultem—but Jaco Products has the experience, knowledge, and equipment to tackle any Ultem project.

PEEK

PEEK can be used as a reliable alternative for metals because of its stiffness, chemical resistance, low moisture absorption, and resistance to biodegradation. PEEK requires annealing before machining but can be machined to a high accuracy to very tight tolerances. You can find PEEK in aerospace, automotive, chemical, electronics, energy, and healthcare industries.

Nylon

Nylon can be difficult to machine because it deforms easily from being held in position but offers extremely tight tolerances and high strength and dimensional stability. Jaco Products has plenty of experience machining nylon and we are happy to work with this material to produce your part.

Custom ABS Parts

One of the primary advantages of producing custom ABS plastic parts lies in the unparalleled design flexibility it offers. Manufacturers like Jaco Products employ advanced CAD/CAM software and injection molding techniques to transform client specifications into precise, custom-designed components. ABS plastic parts can be tailored to meet the most demanding requirements, enabling innovation and creativity in product design.

Moreover, ABS plastic parts can be easily customized to incorporate features such as embossed logos, textured surfaces, and color-matched finishes, allowing companies to enhance brand identity and differentiate their products in the marketplace. Whether it’s achieving a specific aesthetic appeal or optimizing functionality, custom ABS plastic parts provide a canvas for innovation and expression.

Acetal Parts

Acetal is a thermoplastic polymer renowned for its high strength, stiffness, and dimensional stability. It exhibits low friction and excellent wear resistance, making it ideal for applications involving moving parts or components subjected to repetitive stress. Additionally, acetal is resistant to a wide range of chemicals, moisture, and solvents, further enhancing its suitability for diverse industrial applications.

The journey of producing custom acetal plastic parts begins with design and engineering. Collaborating closely with clients, manufacturers assess the specific requirements, functionality, and performance criteria of the desired components. This collaborative approach ensures that the final design aligns seamlessly with the client’s needs while leveraging the inherent properties of acetal to optimize performance and durability.

HDPE Plastic Parts

As one of the most versatile thermoplastics available, HDPE offers a myriad of benefits, including exceptional strength, durability, chemical resistance, and versatility. From intricate prototypes to large-scale production runs, the process of crafting custom HDPE plastic parts involves a meticulous blend of cutting-edge technology, skilled craftsmanship, and a deep understanding of material properties.

The selection of the appropriate grade of HDPE is crucial, as variations in molecular weight, density, and additives can significantly impact the performance and properties of the final parts. Working closely with material suppliers, manufacturers ensure that the chosen HDPE resin meets the specific requirements of each project, balancing factors such as mechanical strength, environmental compatibility, and regulatory compliance.

Custom Polycarbonate Parts

Lexan, a brand name for polycarbonate, is a versatile thermoplastic known for its exceptional strength, clarity, and impact resistance. As a material, polycarbonate offers numerous advantages, including high optical clarity, excellent dimensional stability, and resistance to extreme temperatures and weathering. These properties make it an ideal choice for a wide range of applications, from aerospace components to consumer electronics. Whether it’s a simple component or a complex assembly, meticulous attention to detail is crucial at every stage of the design process. CAD (Computer-Aided Design) software is employed to create precise digital models, allowing engineers to visualize and refine the part geometry before production begins.

Custom PTFE Parts

Jaco Products has distinguished itself as a leader in producing custom PTFE (Polytetrafluoroethylene) parts of unparalleled quality and precision. With a legacy of innovation and a commitment to excellence, Jaco Products leverages advanced technologies and engineering expertise to deliver bespoke solutions tailored to the unique needs of its customers. Let’s explore the intricacies of custom PTFE parts production and the role Jaco Products plays in shaping this dynamic industry.

PTFE, commonly known by the brand name Teflon®, is a fluoropolymer with remarkable properties that make it ideal for a wide range of applications. Renowned for its low friction coefficient, excellent chemical resistance, and high temperature stability, PTFE is often used in demanding environments where reliability and performance are paramount.

At Jaco Products, the journey of producing custom PTFE parts begins with a thorough understanding of the customer’s requirements and specifications. Whether it’s a complex component for aerospace applications or a precision seal for medical devices, Jaco’s team of engineers works closely with clients to conceptualize, design, and optimize parts for maximum efficiency and functionality.

Custom Acrylic Parts

Acrylic, also known as PMMA (Polymethyl Methacrylate), is a versatile thermoplastic renowned for its clarity, durability, and aesthetic appeal. Widely used as a substitute for glass due to its lightweight nature and impact resistance, acrylic offers numerous advantages, including optical clarity, UV resistance, and ease of fabrication. These properties make it an ideal material for a wide range of applications, from signage and displays to medical devices and automotive components.

Acrylic can be cut using various methods, including sawing, laser cutting, and CNC routing. Proper cutting techniques are essential to prevent chipping, melting, or cracking of the acrylic. For instance, sawing is ideal for straight cuts on thicker acrylic sheets, while laser cutting offers precision for intricate designs.

Drilling and milling acrylic can be done using standard woodworking tools. It’s important to use sharp drill bits and low drilling speeds to avoid cracking or shattering the acrylic. Cooling the acrylic with water or lubricating oil can help prevent overheating during drilling and milling operations.

Acrylic can be bent using heat or cold bending techniques. Heat bending involves heating the acrylic sheet until it becomes pliable and then bending it to the desired shape. Cold bending, on the other hand, is suitable for thinner acrylic sheets and involves scoring the acrylic along the bend line before bending it manually.

Costs Involved with Manufacturing Custom Plastic Parts

The production of custom plastic parts allows for incredible versatility in color, shape, materials, additives, and finishes, making molding a versatile approach to producing your parts. The flexibility in design, combined with low waste—scrap can easily be recycled—allows for a simple and easy-to-implement process. Molds can be expensive to produce, however, as can ancillary products such as mold and platen insulation. But once the setup is complete, the molding process is inexpensive, sustainable, and efficient.

Custom Machined Parts from Jaco Products

Get the high-end, tight tolerance machined plastic parts you need. We are your one-stop shop for all your component part needs. When you need tailor made high-performance parts, get in touch with us.

Our work is built on decades of quality, precision, and craftsmanship. Our parts have performed in hundreds of specialty applications, and we accept challenges that many other plastics manufacturers would turn away. If you have a complex part, or you’re working with a sophisticated or difficult material, make sure you call us to help you with the molding and machining you need to make your product a success.

Plastic Materials We Work With

Jaco specializes in the CNC plastic machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

- Udel

- UHMWPE

- Acrylic

- Ultem

For Your Plastic Machining Needs, Turn to Jaco

There is quality in every part we machine and we maintain a complete record of each and every product.

If you would like to know more about Jaco and our plastic machining abilities, call us today.