What Is PEEK Plastic?

PEEK plastic, also known as polyether ether ketone, is ideal for components used in harsh environments that require excellent chemical resistance over a wide range of temperatures. PEEK is an engineered resin designed to perform well in applications that require hydrolysis resistance while maintaining stiffness with PEEK temperature limits up to 170°C / 338°F.

PEEK Material Specifications & Mechanical Properties

PEEK plastic is a strong, stiff, semi-crystalline thermoplastic with a highly stable chemical structure offering a high chemical resistance and temperature limits suitable for a wide range of applications and industries.

- Chemical resistant

- Hydrolysis resistant

- Radiation resistant

- Autoclavable, resilient when exposed to boiling water and exposure to hot steam

- Fatigue and stress-crack resistant

- Creep resistant

- Low moisture absorption

- Low coefficient of linear thermal expansion

- Stable at elevated temperatures up to 170°C / 338°F

- UL 94 V-0 flammability rating

- Low toxic gas and smoke emissions

- Lightweight and chemically inert

- Dimensionally stable

- Controlled porosity

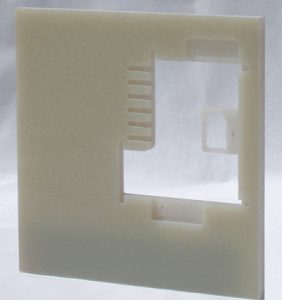

- Appearance white to off-white/natural

- Easy to fabricate and machine

PEEK Plastic Properties

| UNITS | ASTM TEST | PEEK | PEEK 30% GLASS-FILLED |

|

| PEEK tensile strength | psi | D638 | 14,000 | 24,620 |

| PEEK flexural modulus | psi | D790 | 590,000 | 1,450,000 |

| PEEK Izod impact (notched) | ft-lbs/in of notch | D256 | 1.6 | 1.84 |

| PEEK heat deflection temperature @ 264 psi |

°F | D648 | 306 | 599 |

| Maximum continuous service temperature in air |

°F | 480 | 482 | |

| Water absorption (immersion 24 hours) |

% | D570 | 0.50 | 0.11 |

| PEEK coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 2.6 | 1.2 |

| PEEK coefficient of friction (dynamic) | 0.25 | 0.30 | ||

** Values may vary by PEEK material brand/molding conditions. Refer to the specific manufacturer’s PEEK plastic material data sheet for exact values.

PEEK Product Applications

PEEK offers unique properties making it an ideal solution for a wide range of applications that require high-temperature, chemical, UL rating, stiff, tough and creep-resistant materials.

PEEK plastic applications across these industries:

- Nuclear

- Oil and gas

- Medical and pharmaceutical

- Aerospace

- Semiconductor

- Food processing

- Filter manufacturing

PEEK component types include:

- Machinery and equipment components

- Rings and seals

- Bushings and bearings

- Instrument parts

- Downhole electrical components

- Biodiesel filters

Grades of PEEK Plastic

PEEK, Unfilled Virgin

Naturally abrasion-resistant, unfilled, virgin PEEK material provides wear and steam resistance. Of all the PEEK grades, unfilled PEEK provides the greatest toughness and elongation.

PEEK, 30% Glass-Fiber-Reinforced, 30% Glass-Filled PEEK

30% glass-filled PEEK offers a reduced expansion rate and increased flexural modulus. Ideal for structural applications looking for stiffness and stability at higher temperatures.

PEEK, 30% Carbon-Fiber Reinforced

Carbon fiber reinforced PEEK increases wear-resistance, greater thermal conductivity, and a lower expansion rate.

PEEK, Graphite Reinforced Bearing Grade

Bearing grade PEEK reinforced with graphite and PTFE lubricants offers low friction, low wear, high LPV, and low mating part wear.

PEEK Machining, Plastic Fabricator, And Injection Molding

PEEK plastic can be CNC machined, molded and fabricated. Jaco offers PEEK molding, drilling, milling, and machining services to either cut to size, mold or machine to your CAD drawings. We can injection mold both filled and unfilled PEEK components. Get an estimate on custom PEEK machining services from a premier Ohio PEEK fabricator.

PEEK Distributor | PEEK Material Supplier

We sell full sheets of PEEK plastic through our materials distribution and fabrication service. We offer varying thicknesses of PEEK material. Please contact of sales department regarding available inventory.

PEEK Datasheet / Technical Information

Contact our experienced technical staff for the most up-to-date copy of a PEEK material datasheet. Our staff is available to help you specify the right materials for your application and design the PEEK parts/components to meet your product requirements. Contact our technical staff today to discuss your PEEK part design.