Machining to Meet Your Needs

Jaco Products specializes in CNC plastic machining, delivering precision plastic components built to match your exact specifications. Unlike general CNC shops that prioritize metals, we focus on achieving the best results with plastics. Our combined expertise in injection molding and plastic CNC machining allows us to offer reliable, custom solutions. If you’re looking for plastic CNC machining near me, Jaco Products is your trusted partner for quality and precision.

Choose a Manufacturer that Specializes in CNC Plastic Machining

For over 70 years, Jaco has been the trusted plastic component fabricator and leader in CNC plastic machining services. We deliver precision-engineered solutions for demanding industries nationwide. Businesses consistently choose Jaco for our proven expertise and advanced technical capabilities. We manufacture highly durable parts that meet the most rigorous specifications. This includes everything from high-performance production components to complex prototypes.

Count on Jaco to provide complete solutions for your engineering and CNC plastic machining needs. We feature a precision-focused CNC machining shop. Our reliable machining capabilities provide customers with quality machined parts. We can create custom programs directly from your files or drawings to ensure the accuracy of every finished product you receive.

Request a Quote

Does Your Company Have CNC Plastic Machining Needs?

Get your plastic parts made no matter how complex. With state-of-the-art equipment and fundamental knowledge of plastic machining, Jaco is your manufactured plastics solution.

What is CNC Plastic Machining?

CNC stands for computer numerical control. It is a highly specialized machining process where pre-programmed software feeds exact directions to tools and machinery. This automated process creates highly accurate products. Because CNC machining is incredibly effective, it is widely utilized across a vast range of critical industries. The CNC software directly controls grinders, lathes, mills, and other advanced equipment.

CNC plastic machining allows complex three-dimensional cutting tasks to be completed in a single set of automated prompts. For that exact reason, engineers heavily prefer it for highly complex parts. Manual machining requires an operator to physically guide the machine. With CNC plastic machining, that extra labor requirement is eliminated. The equipment can complete intricate manufacturing tasks entirely automatically.

CNC Plastic Machining Types

CNC machining for plastic productions can use a number of different tools and operations. Whether you need to complete PEEK CNC machining or a different type of CNC plastic process, here are some machines that may be utilized.

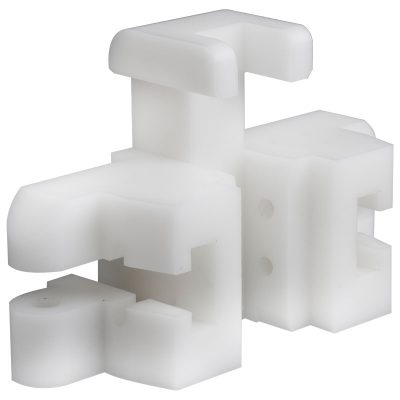

Plastic CNC Machining Parts

Jaco Products specializes in working with a vast range of industrial plastics. CNC plastic machining is a subtractive manufacturing process. It begins with a solid block of raw plastic. As the computer feeds the machine specific directions, the block is strategically cut and shaped down to its intended final form.

The cutting tools used for plastic CNC machining parts need to be precise and uniform. CNC machining is popular because it can replicate parts quickly and accurately no matter how complicated they are. CNC plastic machining works with incredibly tight tolerances to create a range of parts in industries like medicine, food and beverage services, and aerospace.

So what materials can be used for plastic CNC machining parts? Here are some common plastics:

PEEK Plastic: PEEK is a high-performance thermoplastic that has excellent machining properties and can withstand chemical changes better than most other plastics.

Nylon: Nylon refers to a broad category of low-friction engineering thermoplastics that have a high impact strength. Nylon is often used for CNC plastic machining because it can withstand wear and tear and doesn’t react poorly to oil and fuel.

Delrin: Delrin is the shorthand name for acetal resins that are semi-crystalline thermoplastic polymers. When it comes to plastic CNC machining parts, Delrin is a popular choice because it can create stiff parts, has low friction, and has high dimensional stability.

CNC Plastic Milling Services

Our CNC plastic milling services leverage computer‑controlled machining to precisely shape plastic materials into custom parts straight from your CAD designs. CNC milling is a subtractive process where advanced mills remove material from solid plastic stock to produce complex geometries, intricate features, and consistent results that meet tight tolerances – making it ideal for both prototypes and production components.

We work with a broad selection of engineering plastics – such as polycarbonate, nylon, acrylics, PTFE, and more – chosen for properties like chemical resistance, durability, and electrical performance to fit your application needs.

This flexibility means CNC plastic milling is suitable for one‑off prototypes, functional testing parts, and medium‑volume runs where precise detail and repeatability are critical. The automated process also delivers excellent surface quality and speed, helping accelerate project timelines without sacrificing quality.

Plastic Materials We Work With

Jaco specializes in the CNC plastic machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

Material Properties

| Material | Properties & Applications | Inquiry |

|---|---|---|

| ABS | A versatile, impact-resistant thermoplastic frequently chosen for its excellent dimensional stability and ease of fabrication in industrial housing. | Request a Quote |

| FR4 | A fire-retardant glass-reinforced epoxy laminate that provides high dielectric strength and reliable electrical insulation in both dry and humid conditions. | Request a Quote |

| G-10 | A high-pressure industrial laminate with exceptional mechanical strength and low moisture absorption, ideal for structural and electrical components. | Request a Quote |

| Nylon | Engineered for durability, this material provides superior wear resistance and low-friction performance for bearings, rollers, and mechanical parts. | Request a Quote |

| PEEK | An ultra-high-performance polymer capable of maintaining structural integrity and chemical resistance in extreme thermal environments up to 480°F. | Request a Quote |

| PET | A rigid plastic noted for its impressive tensile strength and dimensional stability, making it a preferred choice for precision machined components. | Request a Quote |

| PMMA (Acrylic) | Offers exceptional optical clarity and UV resistance, serving as a lightweight, shatter-resistant alternative to traditional glass. | Request a Quote |

| Polycarbonate | A virtually unbreakable transparent polymer that combines high-impact toughness with heat resistance for safety and security applications. | Request a Quote |

| Polyethylene | Available in various densities (HDPE/UHMW), this material provides high chemical resistance and excellent impact strength for diverse industrial uses. | Request a Quote |

| Polypropylene | Noted for its fatigue resistance and chemical purity, this material is ideal for fluid handling systems and laboratory equipment. | Request a Quote |

| POM (Delrin/Acetal) | A high-crystallinity thermoplastic that bridges the gap between plastics and metals with its high stiffness and superior machining accuracy. | Request a Quote |

| PTFE (Teflon) | A non-reactive fluoropolymer that offers one of the lowest coefficients of friction against any solid, providing extreme temperature and chemical stability. | Request a Quote |

| PVC | A cost-effective, rigid material with excellent resistance to weathering and chemicals, widely utilized in plumbing and industrial construction. | Request a Quote |

Advanced CNC Plastic Machining Capabilities

We actively utilize 5-Axis CNC machining methods at our advanced plastic manufacturing center. This allows us to create extreme precision prototypes and complex components with total ease. We also offer these specialized services at highly competitive pricing regardless of your total order volume. Furthermore, our deep knowledge surrounding thermoplastic and thermoset materials allows us to perfectly customize your plastic components to your exact application requirements.

Why Choose Jaco Over Other Plastic Machining Companies?

In addition to high-quality products and machining processes, we offer:

- Advanced quality control processes that meet and outperform industry standards

- Full-service machining from assistance with product development to final production

- Advanced CNC manufacturing equipment

- Vendor-managed inventory systems for supporting your process.

- Custom packaging options

- Total dedication to customer satisfaction with every project.

Jaco Products maintains a leading position in the plastic machining industry by offering unmatched precision and versatility. As a result, we can tackle the most unique and complex applications and projects. Our innovative approach to plastic CNC machining yields effective solutions for any manufacturing project.

Turn to Jaco for Your Plastic Machining Needs

We process and machine all parts in a completely controlled environment. There is quality in every part we machine and we maintain a complete record of each and every product.

If you would like to know more or you are interested in learning about Jaco and our plastic machining abilities, call us today.