Machining to Meet Your Needs

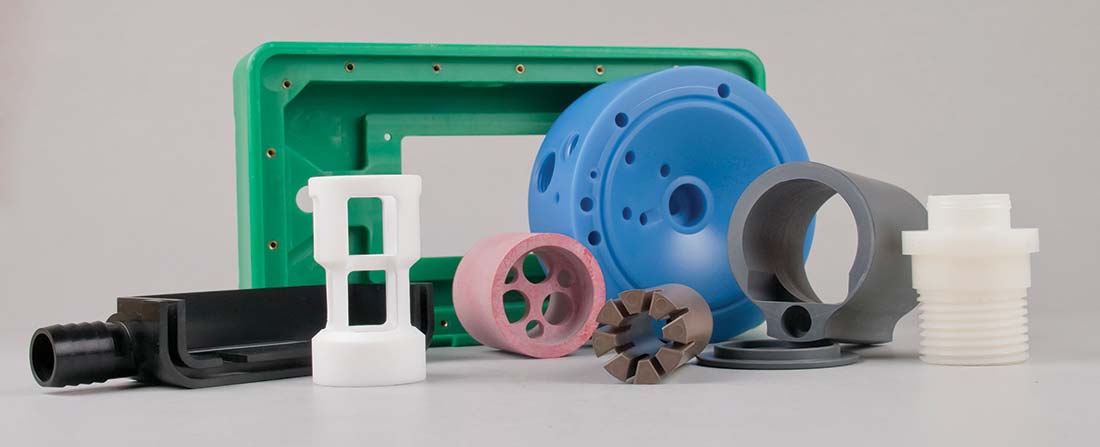

At Jaco Products, we specialize in CNC plastic machining, delivering precision-crafted components tailored to your exact specifications. Unlike standard CNC shops that focus primarily on metals and view plastic machining as secondary, we prioritize achieving superior results with plastics. While many manufacturers depend solely on injection molding, Jaco Products stands out with a unique combination of expertise in both injection molding and plastic CNC machining near me, offering a reliable and versatile solution for your specific needs.

Choose a Manufacturer that Specializes in CNC Plastic Machining

For more than 70 years, Jaco has been providing CNC plastic machining as a plastic component fabricator. We have unparalleled knowledge of thermoset and thermoplastic engineered materials and our machining capabilities include 5-axis machining, routing, milling, and turning with precision tolerances of .0001″. We continue to invest in advanced equipment that enables us to handle high tolerance requirements, fulfilling small and large volume projects at competitive pricing.

Count on Jaco to provide complete solutions for your engineering and CNC plastic machining needs. We feature a precision-focused CNC machining shop. Our reliable machining capabilities provide customers with quality machined parts. We can create custom programs directly from your files or drawings to ensure the accuracy of every finished product you receive.

Does Your Company Have CNC Plastic Machining Needs?

Get your plastic parts made no matter how complex. With state-of-the-art equipment and fundamental knowledge of plastic machining, Jaco is your manufactured plastics solution.

What is CNC Plastic Machining?

CNC stands for computer numerical control, and is a machining process in which a pre-programmed software feeds directions to tools and machinery to create products. Because CNC machining is so effective, it’s used in a range of industries and processes. CNC can control grinders, lathes, mills, and more.

CNC plastic machining allows three dimensional cutting tasks to be done in a single set of prompts. For that reason, it’s preferred for more complex parts. Manual machining requires that an operator be there to guide the machine. With CNC plastic machining, there is no longer the need for the extra labor; it can complete tasks automatically.

CNC Plastic Machining Types

CNC machining for plastic productions can use a number of different tools and operations. Whether you need to complete PEEK CNC machining or a different type of CNC plastic process, here are some machines that may be utilized.

Lathes: A lathe machine cuts pieces in a circular direction using indexable tools. Using CNC plastic machining, the lathes cut with precision and high velocity. CNC plastic operations can produce far more complex designs that are difficult and time consuming to achieve with manual machines.

Plasma Cutter: A plasma cutter works by using a plasma torch to cut material. As opposed to CNC machine for plastic productions, the plasma cutter is most often used in metal processing.

CNC Mills: A CNC mill runs based on number and letter prompts that guide pieces and parts across distances. The most basic CNC mills use a three-axis system (X,Y,Z) to shape parts. However, more advanced CNC plastic technology can sometimes incorporate up to three additional axes.

Plastic CNC Machining Parts

Jaco Products specializes in working with a range of plastics. CNC plastic machining is a subtractive manufacturing process that begins with a solid block of plastic. As the computer feeds the machine directions, the block is cut and shaped down to its intended form.

The cutting tools used for plastic CNC machining parts need to be precise and uniform. CNC machining is popular because it can replicate parts quickly and accurately no matter how complicated they are. CNC plastic machining works with incredibly tight tolerances to create a range of parts in industries like medicine, food and beverage services, and aerospace.

So what materials can be used for plastic CNC machining parts? Here are some common plastics:

PEEK Plastic: PEEK is a high-performance thermoplastic that has excellent machining properties and can withstand chemical changes better than most other plastics.

Nylon: Nylon refers to a broad category of low-friction engineering thermoplastics that have a high impact strength. Nylon is often used for CNC plastic machining because it can withstand wear and tear and doesn’t react poorly to oil and fuel.

Delrin: Delrin is the shorthand name for acetal resins that are semi-crystalline thermoplastic polymers. When it comes to plastic CNC machining parts, Delrin is a popular choice because it can create stiff parts, has low friction, and has high dimensional stability.

Plastic Materials We Work With

Jaco specializes in the CNC plastic machining of:

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

CNC Plastic Machining

We utilize 5-Axis CNC machining methods at our advanced plastic manufacturing center, so we can create precision prototypes and components with ease. We also offer these services at competitive pricing regardless of volume. Furthermore, our knowledge surrounding thermoplastic and thermoset materials allows us to customize your plastic components to your application’s requirements.

Why Choose Jaco Over Other Plastic Machining Companies?

In addition to high-quality products and machining processes, we offer:

- Advanced quality control processes that meet and outperform industry standards

- Full-service machining from assistance with product development to final production

- Advanced CNC manufacturing equipment

- Vendor-managed inventory systems for supporting your process.

- Custom packaging options

- Total dedication to customer satisfaction with every project.

Jaco Products maintains a leading position in the plastic machining industry by offering unmatched precision and versatility. As a result, we can tackle the most unique and complex applications and projects. Our innovative approach to plastic CNC machining yields effective solutions for any manufacturing project.

Turn to Jaco for Your Plastic Machining Needs

We process and machine all parts in a completely controlled environment. There is quality in every part we machine and we maintain a complete record of each and every product.

If you would like to know more or you are interested in learning about Jaco and our plastic machining abilities, call us today.