Delrin is a trademark for a type of acetal resin introduced by the chemical giant DuPont in the 1950s. This high-performance thermoplastic material is renowned for its strength, rigidity, and low friction coefficient. Due to its durability and cost-effectiveness, Delrin is frequently used as an alternative to metals and other materials that are heavier, more expensive, or more susceptible to wear.

The chemical name for Delrin plastic is polyoxymethylene (POM), which is a type of polymer that is created by polymerizing formaldehyde. Delrin has a crystalline structure that makes it particularly strong and resistant to impact and abrasion. It is also resistant to chemicals, moisture, and temperature fluctuations, which makes it ideal for use in a wide range of industrial applications.

Advantages of Delrin Plastic

One of the key advantages of Delrin is its strength and stiffness. It has a high tensile strength, which means it can withstand a lot of stress and tension without breaking. This makes it useful in applications where high loads or forces are involved, such as gears, bearings, and other mechanical components. Delrin is also very stiff, which means it does not deform or bend easily. This makes it useful in applications where precision and accuracy are important, such as in machining or molding.

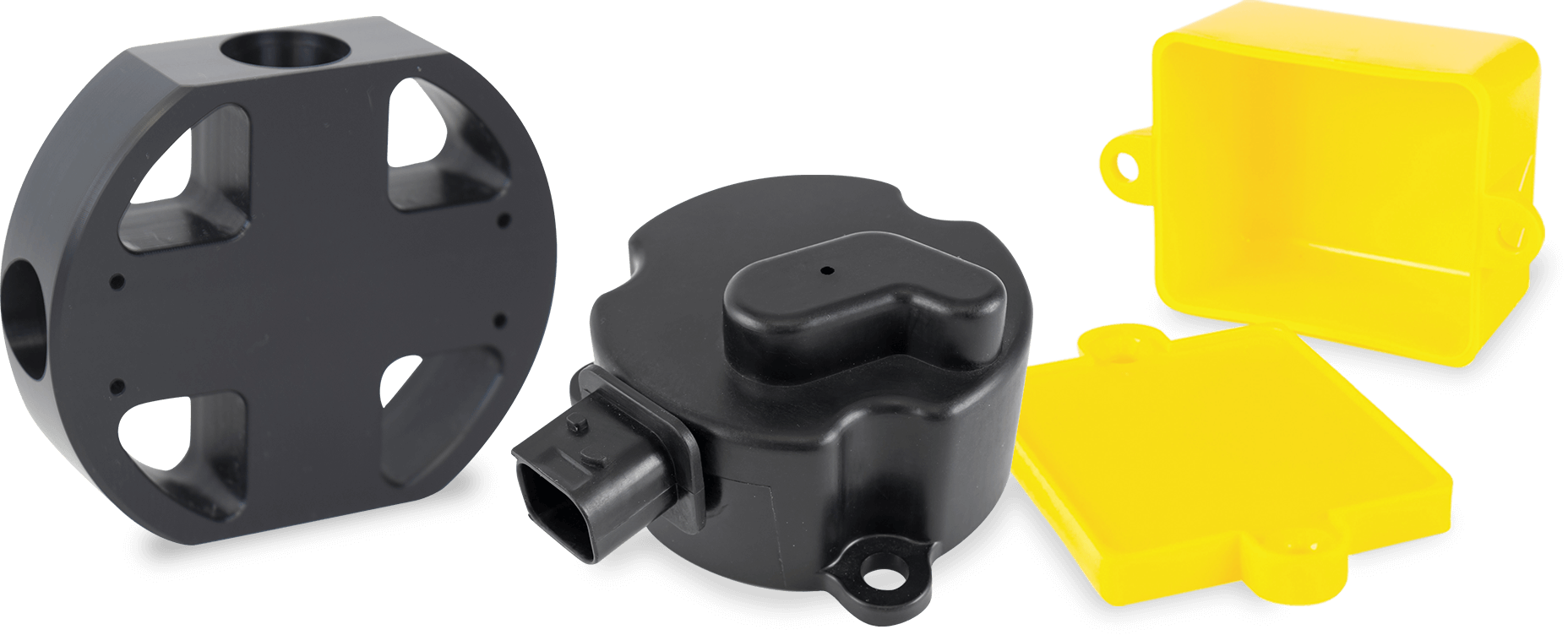

Delrin is also very easy to machine, which means it can be cut, drilled, and shaped using standard machining techniques. It can also be injection molded into complex shapes, which makes it useful in a wide range of manufacturing applications. Delrin is also available in a range of colors and grades, which makes it easy to customize for specific applications.

One of the disadvantages of Delrin is that it can be prone to cracking or fracturing if it is exposed to certain chemicals or if it is exposed to high temperatures for prolonged periods of time. It is also not as resistant to UV radiation as some other materials, which means it may not be suitable for outdoor applications. However, these limitations can be mitigated by choosing the right grade of Delrin and by taking appropriate measures to protect it from environmental factors.

Why Choose Jaco as your Plastic Products Supplier?

Our modern, well-maintained lineup of equipment and professional staff allows us to offer service second to none. Give us a try on your next plastic project.

Some of The Key Advantages of Delrin Plastic Include:

Strength and stiffness: Delrin has a high tensile strength and is very stiff, making it ideal for use in applications where high loads or forces are involved and where precision and accuracy are important.

Low coefficient of friction: Delrin has a very low resistance to sliding or rubbing against other surfaces, making it ideal for use in applications where low friction is important, such as in bearings, bushings, and other moving parts.

Resistance to chemicals and moisture: Delrin is resistant to many chemicals and moisture, making it ideal for use in harsh environments and applications where exposure to chemicals or moisture is a concern.

Dimensional stability: Delrin does not shrink or expand much with changes in temperature or humidity, making it useful in applications where tight tolerances are required.

Easy to machine: Delrin is very easy to machine, which means it can be cut, drilled, and shaped using standard machining techniques. It can also be injection molded into complex shapes, which makes it useful in a wide range of manufacturing applications.

Customizable: Delrin is available in a range of colors and grades, which makes it easy to customize for specific applications.

Overall, Delrin is a versatile and reliable material that has proven to be useful in a wide range of industrial applications. Its strength, stiffness, low coefficient of friction, resistance to chemicals and moisture, dimensional stability, and ease of machining and customization make it a popular choice for many different applications.