Get Precision Plastics Parts Made in America

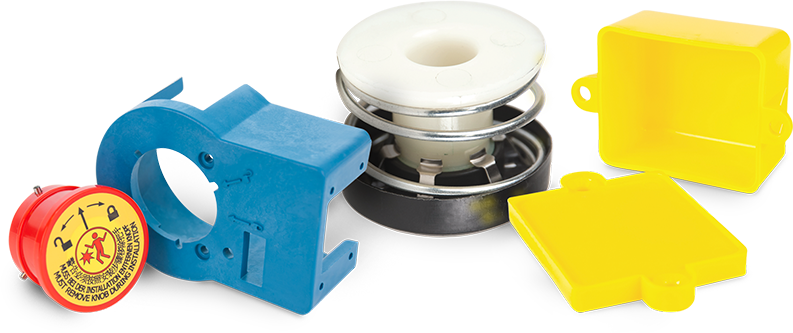

When looking for reliable plastics manufacturers nearby, it’s crucial to choose a partner with proven expertise to help your business succeed in the competitive plastics sector. Whether you need injection molding, plastic stamping, or full-scale plastic distribution services, Jaco Products is the trusted name you can count on.

If you are searching for a plastics manufacturer near me, Jaco Products stands out as more than just a supplier. We are your local partner in precision and innovation. Whether your project involves injection molding, plastic stamping, or comprehensive plastic distribution, we offer a complete suite of services and uphold the highest standards.

From simple components to complex high-volume production, Jaco combines expertise, quality, and reliability to bring your vision to life.

Don’t just take it from us. Let’s talk about some of the services and standards that have earned Jaco Products the reputation as a trusted plastic manufacturer in Ohio.

Services Offered By Jaco Products

Depending on the demands of your business, finding the right plastics manufacturer near me can be challenging, but Jaco makes that decision simple. With advanced machinery, refined processes, and a commitment to excellence, we handle everything from custom injection molding to thermal mold and platen insulation, delivering on-time and competitively priced results without compromising quality.

No matter the complexity of your part or project, we can get the job done. When other plastic manufacturers near me say they “won’t quote” your project, Jaco will. Take a look at some of the services we offer.

Plastic Machining

Here at Jaco, we offer quality plastic machining services for standard parts and advanced, customized materials. At every step of the machining process, we ensure that our product is up to standard and capable of performing at a high level.

Jaco offers CNC plastic machining, which stands for “Computerized Numerical Control.” This means that this equipment automates fabrication tasks when needed. CNC machining is known as one of the most precise plastic fabrication methods and it allows for high-volume production of complex plastic parts.

Because we pride ourselves on innovation and quality, Jaco is fully equipped to meet projects with the highest tolerance requirements. Furthermore, we offer quick turnaround on these projects, even if you need a large volume. It’s these high standards that set us apart from other plastic manufacturers near me, and make us a top choice when you need CNC machining or other plastic services.

Plastic Stamping and Die Cutting

We offer plastic stamping of non-metallic production components. Our stamping ranges from 18 through 16 tons, which means we can stamp up to the maximum thickness possible. Because of the range this service provides, Jaco serves a variety of industries, from aerospace technology to small appliance manufacturers. No project is too big or too complex for our team.

Our team has an in-house facility capable of building and designed a matched metal stamping die. We maintain most stamping dies for the life of the production component, and throughout your project our staff is there every step of the way to answer questions.

Due to our stamping capabilities, we can design the proper dies (progressive or compound), and achieve precision tolerances your team needs. From initial recommendations, through prototypes, and to the finished product — the Jaco team has got you covered.

Plastic Injection Molding

Need plastic manufacturers near me to tackle a complex injection molding project? Jaco is the answer. We offer custom injection molding of thermoplastic materials up to 29 oz, and we have built a reputation for taking on projects that others “No Quote.”

Jaco has the ability to mold high-temperature materials like Ultem and Polysulfone. This means that, if your project uses intricate parts with tight tolerances, there’s no need to worry if you can get a manufacturer to take it on. You can trust that our experts have a thorough understanding of insulator materials, plastic injection molding, and electrical insulator design.

What’s The Jaco Process?

There’s a reason that we’re known as one of the leading plastic manufacturers near me. Jaco Products began in 1948 as a plastic molding company dedicated to mastering precision plastics and molding technology. Since then, we have worked toward our mission of providing world-class custom plastic injection molding services to any and all industries that need it.

Jaco has in-house facilities for tool design, CNC machining, and fixture manufacturing, which means we perform much of our operations from a single location. We like to call ourselves a “one stop shop: for your custom injection molding needs. We also utilize computer-aided manufacturing CAM and CAD to facilitate our manufacturing. Our capabilities mean our product gallery is vast, and throughout our years as a business we’ve aided a multitude of industries.

Though our services differ, the backbone of the Jaco process is teamwork and expertise. We want to offer customers much more than a “service.” We want you to experience what Jaco Products has to offer, which includes a friendly staff with years of knowledge about plastic manufacturing. As we take your project from start to finish, we want you to ask questions along the way, and learn more about our processes. We want you to have a pleasant experience with our staff and technology, no matter the size or scope of your project.

Why Jaco Products?

Why do industries trust Jaco Products as one of the top plastic manufacturers near me? Not only do we provide a variety of plastic manufacturing services, but we are constantly innovating to tackle your most specific project needs.

In addition, Jaco Products is proud to provide quick turnaround times at a competitive price. We want to ensure you get the quality of products you need at an affordable rate, and we are proud to offer just that.

From plastic molding to complex materials, Jaco’s knowledge and experience makes us an industry leader. Come see for yourself and give us a call today!

Plastic Materials That Can Be Machined

- Delrin

- Nylon 6/6, 6, 6/12

- HDPE

- FR-4

- G-10

- PEEK

- Lexan/Polycarbonate

- PTFE

- Teflon

- Udel

- UHMWPE

- Acrylic

- Ultem

Injection Molding Materials:

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal; Celcon, Delrin injection molding

- Polyamide: Nylon 6/6; Zytel injection molding

- Polyamide: Nylon 6/6, glass filled LGF nylon injection molding

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Polycarbonate (PP) Lexan, Makrolon

- Polycarbonate/ABS Alloy

- Polyetherimide: Ultem injection molding

- Polyetherimide, fiber reinforced; Ultem

- Polybutylene Terephthalate; Valox, Crastin

- Polypropylene: Maxxam, Profax

- Polystyrene: Styron

- High-Impact Polystyrene: HIPS

- Thermoplastic Elastomer: Isoplast, Santoprene Acrylic; Plexiglass, Acrylite

Stamping Materials:

- Nomex®

- Mylar®

- Polyester

- Kapton®

- Polyamide Film

- Vulcanized Fiber

- FR-4

- GPO-1

- GPO-2

- GPO-3

- SG-200

- HST II

- Ultratrac®