Delrin vs Nylon: A Comparative Analysis in Plastic Machining

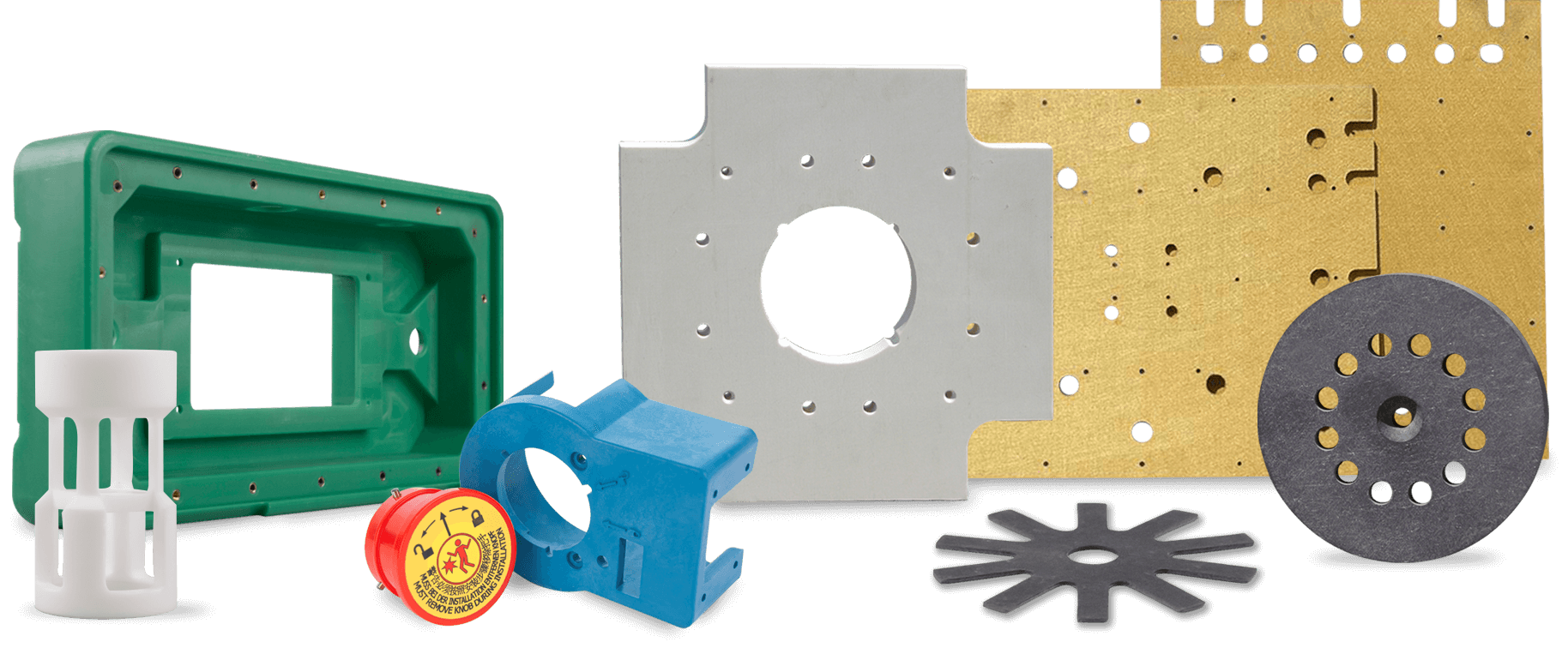

In the world of plastic machining, selecting the right material is essential for ensuring precision, durability, and performance. Delrin (Polyoxymethylene, POM) and Nylon are two of the most widely used thermoplastics in CNC machining due to their unique properties. This analysis dives into the characteristics of Delrin and Nylon specifically within the realm of plastic machining, helping manufacturers choose the right material for their projects.

Delrin in Plastic Machining

Delrin is a highly machinable thermoplastic that offers excellent dimensional stability and rigidity, making it a go-to material for precision machining.

Key Benefits of Delrin in Machining:

- Dimensional Stability: Delrin holds its shape well throughout the machining process, even under tight tolerances. This makes it ideal for precision parts that require accuracy over extended production runs.

- Low Friction and Wear Resistance: Delrin’s low coefficient of friction is advantageous in moving parts, such as gears and bearings, where minimizing wear is critical.

- Smooth Surface Finishes: Delrin allows for high-quality surface finishes with standard CNC milling, turning, and drilling, reducing the need for extensive post-processing.

- Ease of Machining: Delrin machines well on standard CNC equipment, without the need for special tooling or cutting fluids, making it both cost-effective and efficient.

Why Choose Delrin for Machined Parts?

Delrin is ideal for applications where precision, low friction, and durability are key. Its resistance to moisture and chemicals ensures consistent performance during machining, and its dimensional stability makes it suitable for parts requiring high accuracy.

Nylon in Plastic Machining

Nylon, though slightly less rigid than Delrin, offers a balance of flexibility and toughness that makes it suitable for a wide range of machined parts.

Key Benefits of Nylon in Machining:

- Toughness and Flexibility: Nylon’s ability to absorb shock and impact during machining allows for parts that need to endure dynamic loads, such as bushings or protective casings.

- Versatility in Machining: Nylon can be machined into a variety of shapes and components, offering flexibility in part design and application.

- Good Surface Finish: Nylon produces a reasonably good surface finish during CNC operations, although it may require more attention to detail in certain cases compared to Delrin.

- Lightweight Properties: Nylon’s lighter weight makes it an ideal choice for parts that need to reduce overall system weight while maintaining durability.

Why Choose Nylon for Machined Parts?

Nylon is best for applications where flexibility and impact resistance are critical, such as in industrial or consumer goods. While it doesn’t offer the same rigidity as Delrin, it provides excellent performance in parts that experience repeated stress and movement.

Delrin vs Nylon in Machining: A Direct Comparison

When comparing Delrin vs Nylon in plastic machining, the following considerations come into play:

- Machinability: Delrin is easier to machine with higher precision, especially in high-tolerance applications. Nylon, though machinable, may require more attention due to its higher moisture absorption and flexibility.

- Dimensional Stability: Delrin maintains its shape better during and after machining, making it the superior choice for parts requiring tight tolerances. Nylon may experience slight dimensional changes, particularly in humid environments.

- Friction and Wear: Delrin’s low friction makes it the preferred material for parts involving movement, such as gears and bearings. Nylon is more suitable for components where toughness is needed but isn’t constantly in motion.

- Surface Finish: Delrin allows for smoother surface finishes right off the machine, reducing the need for post-processing. Nylon can still achieve a quality finish but may need additional care in some applications.

Applications in Machining: Delrin vs Nylon

Delrin Machined Parts:

- Precision Gears and Bearings: Delrin’s strength, low friction, and wear resistance make it perfect for gears and bearings that need to perform reliably over long periods.

- Valves and Fittings: Delrin’s ability to hold tight tolerances makes it a favorite for parts where sealing and dimensional accuracy are crucial.

Nylon Machined Parts:

- Bushings and Washers: Nylon’s toughness and flexibility are ideal for parts that need to absorb impact while maintaining functionality.

- Custom Fittings: Nylon’s versatility in machining makes it a good choice for custom-designed parts that require resilience but not the same level of precision as Delrin.

Delrin Material vs Nylon in Plastic Machining: Which to Choose?

In the space of plastic machining, the decision between Delrin material vs Nylon depends heavily on the requirements of the part being produced. Delrin is typically the best choice for projects where high precision, dimensional stability, and low friction are essential. It’s a staple in industries like automotive and aerospace, where machined parts must withstand rigorous conditions without losing accuracy.

On the other hand, Nylon shines in applications where flexibility, impact resistance, and toughness are key factors. Nylon is often used in industrial and consumer products, where machined parts must endure repeated movement or stress without breaking down.

In the realm of plastic machining, both Delrin and Nylon offer significant benefits, but they excel in different areas. Delrin provides superior precision, wear resistance, and stability, making it the preferred material for high-precision machined parts. Nylon, with its toughness and flexibility, is an excellent choice for components that need to withstand impact and stress.

At Jaco Products, we specialize in machining high-quality parts from both Delrin and Nylon. Contact us today to discuss which material is the best fit for your next project and how we can help you achieve exceptional results with precision machining.