ABS Plastic Molding Services at Jaco

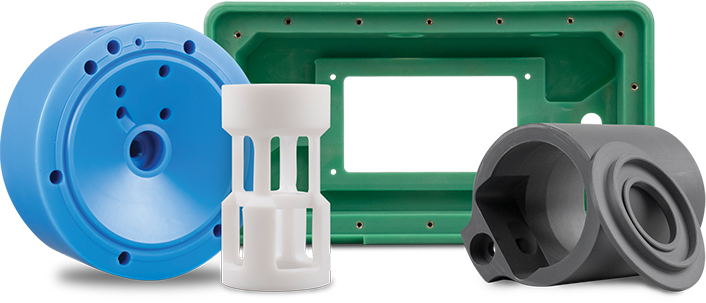

Jaco Products, a trusted ABS plastic molding manufacturer in Ohio, provides high-quality custom ABS plastic molding and machining services. As a durable thermoplastic material, ABS (acrylonitrile butadiene styrene) is valued for its outstanding mechanical strength, impact resistance, and long-lasting performance in various industrial applications.

About ABS Plastic

ABS is a versatile thermoplastic with excellent dimensional stability and resistance to scratching. It is also more cost-effective than exotic resins, making it ideal for injection molding and machining.

Jaco Products can color ABS plastic to match specific Pantones and finish requirements, giving your parts the exact look and performance you need. In addition to our molding expertise, we also provide ABS fabrication services, allowing us to create fully customized solutions from concept to completion.

Additionally, ABS is recyclable at certain recycling facilities, contributing to environmental sustainability.

ABS Plastic Applications

ABS can be found in many types of products, from consumer products such as golf club heads and protective carrying cases to computer covers. Industrial applications for ABS molded and machined parts span across all industries from automotive interiors to medical, marine, and appliance manufacturing.

ABS Injection Molding

We are experts in injection molding complex materials including standard and glass-filled ABS. We can also mold ABS plastic with glass fibers and additives to increase the strength of the part and operating temperatures as high as 176°f.

Contact Us

ABS Plastic Properties:

| Property | Value |

|---|---|

| Tensile Strength (psi) | 5,000-12,000 |

| Flexural Modulus (psi) | 270,000-380,000 |

| Impact Strength (notched Izod ft.-lb./in.) | 3.0-7.5 |

| Max Temperature (deflection or softening) | 140°-200° F |

| Chemical Formula | (C8H8)x· (C4H6)y·(C3H3N)z) |

| Glass Transition | 105 °C (221 °F) * |

| Typical Injection Molding Temperature | 204 – 238 °C (400 – 460 °F) * |

| Heat Deflection Temperature (HDT) | 98 °C (208 °F) at 0.46 MPa (66 PSI) ** |

| UL RTI | 60 °C (140 °F) *** |

| Specific Gravity | 1.06 |

| Shrink Rate | 0.5-0.7 % (.005-.007 in/in) *** |

ABS Plastic Machining

Machined ABS can create high tolerance complex parts that require 5-axis machining. Jaco Products can quickly and easily machine internal threads, ports, holes and complex shapes that would require multi-slide injection molds in either small prototype quantities or large, lights-out production manufacturing.

ABS Plastic Molding & Machining

When high-tolerance, complex ABS parts are required. Our technical staff will use both processes, ABS molding and 5-axis CNC machining. We first injection mold a net near shape ABS part, then machine the part to the required tolerance, milling ports, threads and undercuts that the part requires. Many times, engineers have brought an ABS part to us that other injection molders have declined to quote. Using multiple processes, we are able to successfully fabricate the part. We can machine short-run prototypes for testing and fit/function analysis prior to investment in ABS injection molds.

ABS Plastic Machining

Machined ABS can create high-tolerance complex parts that can be produced only with 5-axis machining. Internal threads, ports, holes, and complex shapes that would require multi-slide injection molds can quickly and easily be machined in either small prototype quantities or large, lights-out production manufacturing.

In addition, we offer a full range of ABS machining services, including: milling, drilling, sawing, turning, shearing, threading, stamping, and die-cutting.

ABS Plastic Fabrication and Finishing Services

Jaco Products also provides a full range of ABS fabrication and finishing services from welding, pad printing, stamping, and engraving to assembly and kitting. We will coordinate outside services such as metal plating. Furthermore, all parts are manufactured and inspected to our stringent ISO 9001:2008 quality standards.

ABS Plastic Product Engineering

Our experienced technical staff is available to help you design the perfect ABS plastic part for your application. Our depth of knowledge of materials, molding and machining is unparalleled, so we can help develop innovative multi-process solutions for your part design challenges. If you can envision it, we can make it. Contact our technical staff today to discuss your part design.

Other Plastic Materials We Work With

Jaco specializes in molding:

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal; Celcon, Delrin

- Polyamide: Nylon 6/6; Zytel

- Polyamide: Nylon 6/6, glass filled LGF nylon

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Polycarbonate (PP) Lexan, Makrolon

- Polycarbonate/ABS Alloy

- Polyetherimide: Ultem injection molding

- Polyetherimide, fiber reinforced; Ultem

- Polybutylene Terephthalate; Valox, Crastin

- Polypropylene: Maxxam, Profax

- Polystyrene: Styron

- High-Impact Polystyrene: HIPS

- Thermoplastic Elastomer: Isoplast, Santoprene Acrylic; Plexiglass, Acrylite