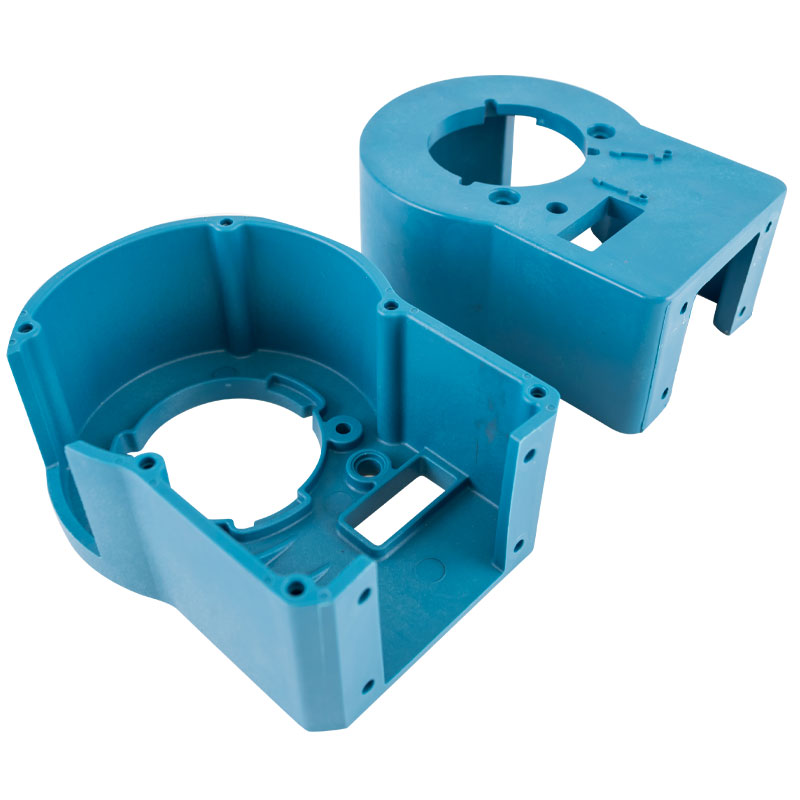

Complex Plastic Parts | Machining Plastic Parts

Turning is a process whereby a workpiece is rotated in a lathe while a stationary tool bit is used to make helical cuts to the material. The most common work performed with turning is drilling and removing the outer edges of a material. While turning can be used to quickly remove material, with precision control it can make intricate cuts that give a perfect machine finish. Turning is used with wood, metals, and plastics, and the tool bit used is normally steel or carbide.

Drilling involves driving a rotating bit into a clamped workpiece. There are many operations that can be performed on a drill press, such as plane drilling, step drilling, core drilling, boring, counterboring, reaming, countersinking, spot facing, tapping, and trepanning. Drilling causes more heat to be produced than other machining methods, so depending on the material, bit, and speed at which the piece is machined, a lubricant and coolant can be used to minimize melting and distortion.

Milling is a process of using a circular cutting bit to cut flat surfaces, grooves, and shoulders into clamped plastic workpieces. Cutting bits are made from either steel or carbide. The cutter moves on an axis and can be manually or CNC controlled. When a material with a low melting point is being worked upon, bits such as a single flute can be used. This minimizes melting by allowing more chips to be produced, which in turn removes more heat from the workpiece.

Plastics generally allow for higher feed rates than metal and are less stressful on machinery and cutting bits. But certain plastics are difficult to machine because they melt, chip, and deform in unpredictable ways while being machined.

Plastics such as Celazole and Torlon are notoriously difficult to machine. Brittle plastics can cause challenges while machining, such as splitting, chipping, or cracking. These materials must be machined more slowly to decrease the stress on the workpiece, and special cutting tools can be used to prevent chipping. Burrs happen when a workpiece is too soft. Burrs can be removed while being machined or can be deburred after the piece is complete. Clamping the workpiece into place can also cause deformation and can even mark the material at the point where the clamp holds the piece. Conversely, ABS, Delrin, and Teflon are much easier to machine.

The dimensions and quality of the raw material also affect machinability. Thin sheet material can warp easily, and often sheet material is not perfectly flat and bar material can be bent. This presents challenges for the machinist that can sometimes be overcome by techniques such as fly cutting to bring the material within specifications.

Many plastics manufacturers will not quote jobs for difficult plastics or complex parts. At Jaco, we have the experience, machinery, and tooling to ensure that we can create your product to extremely tight specifications within a timeframe that is realistic and acceptable. Many of our customers use our services because their current method of machining is producing unsatisfactory results. Our 5-axis CNC plastic machining can produce the part if your current mold design, material, or close tolerance requirements make it impossible to manufacture it with your current method.