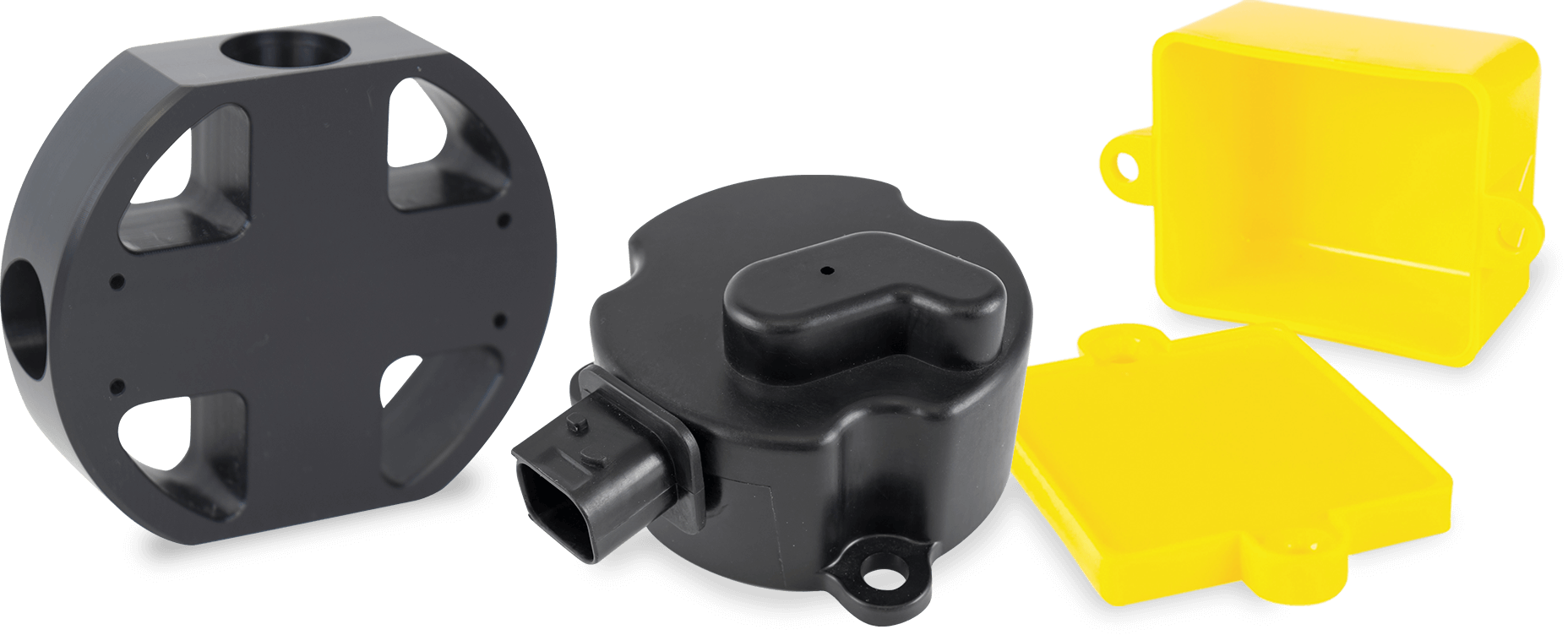

Injection Molded Delrin Enclosure for Blasting

A leading supplier of electronic enclosures for the blasting industry turned to Jaco Products for a challenging application that required precision injection molding of Delrin plastic to meet strict performance demands.

Injection molded Delrin product specifications overview:

The application called for a two-part injection molded Delrin enclosure and a die-cut gasket. Specifications include electrical isolation, flexural strength, and most importantly the ability to remain waterproof at depths of ten feet or more. During the prototype stages, the customer added an additional specification. Accordingly, this called for the enclosure to be field serviceable without the use of special tools.

Jaco achieved this specification by adding external ribs to the enclosure to ensure strength and to retain a castle nut. This allowed the user to service the enclosure in the field without the need for special tools.

Through prototyping and field-testing, we were able to supply an enclosure that met the customer’s specifications. As a result, the enclosure is currently being injection molded in a two-part family mold using Dupont’s Delrin 100. Furthermore, this component is molded under strict guidelines to ensure part integrity and a waterproof enclosure. To aid in waterproofing, Jaco provides a die cut gasket that makes the seal between the lid and the enclosure.

Delrin Injection Molding

Injection-molded Delrin, or Polyoxymethylene (POM), is a high-performance thermoplastic renowned for its strength, durability, and adaptability. Its dimensional stability, resistance to creep and warping, and low moisture absorption make it an ideal choice for parts subjected to harsh environments or heavy wear. Additionally, Delrin’s chemical resistance to fuels and solvents enhances its utility across industries. With compliance in its natural grade to FDA, NSF, and USDA standards, Delrin is suitable for applications requiring strict regulatory adherence.

Key Applications of Delrin Injection Molding

Delrin has transformed industries by replacing materials like zinc, brass, aluminum, and steel with its superior performance and cost-efficiency. In automotive applications, its rigidity and wear resistance ensure durable components like camshafts and connecting rods. In electronics, its insulative properties make it essential for casings and packaging. In healthcare, its biocompatibility and corrosion resistance make it ideal for prosthetics and artificial joints. Delrin’s versatility and reliability cement its status as a top choice for injection molding across sectors.

Can Delrin Be Injection Molded?

Yes, Delrin is an excellent choice for injection molding. Its low friction, high tensile strength, and exceptional dimensional stability make it perfect for creating precise parts like gears, bearings, and medical instruments.

The process is carefully controlled, with temperatures 30–60°C (86–140°F) above Delrin’s melting point to ensure proper flow and minimal shrinkage. This results in durable, high-performance components used across various industries, including automotive, healthcare, and electronics.

Contact Jaco to learn more about our capabilities for Delrin machining and Delrin plastic injection molding.