High-Tolerance Molding Solutions

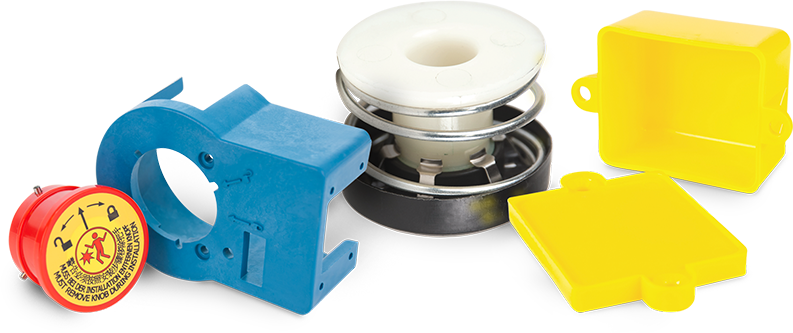

If you need dependable plastic injection molding in Cleveland, Jaco Products is the team you can count on. As a full-service plastic molding company, we deliver custom injection molding solutions for materials up to 29 ounces, ensuring the precision and quality required across a wide range of industries.

Jaco Products has earned a strong reputation for excellence among injection molding Cleveland companies, delivering high-quality plastic components for a wide range of industries. With decades of expertise, we provide advanced molding solutions that ensure durability, precision, and cost-efficiency for every project.

Our experienced technical team works closely with you from concept to completion, providing expert guidance on materials, design, and prototyping. Trust Jaco Products for plastic injection molding Cleveland services that prioritize quality, efficiency, and collaboration.

With a wide range of plastic materials available for the injection molding process, such as polypropylene, polystyrene, polyethylene, and PVC, selecting the best one for your project can be challenging. At Jaco, you receive expert guidance from industry professionals who understand your application and can identify the best materials and design methods to create your product.

Our innovative approach to custom injection molding ensures the utmost precision and uniformity at each step of the design, engineering, and molding process. Our expertise with mold cavities, resin systems, injection molding technology, and processing requirements helps us reduce overall costs while delivering superior results.

What is Injection Molding?

If your project requires custom-molded plastic parts, our team is ready to deliver. We specialize in custom injection molding in Ohio, offering tailored solutions to meet the unique requirements of your application. From prototype development to full-scale production, we guarantee consistent quality and reliable results.

The main advantage of custom injection molding is its ability to accurately produce complex, detailed features. This process also involves much higher pressure than other fabrication processes. As a result, our design experts can more effectively create intricate designs. Injection molded parts have reduced plastic density as well as enhanced durability.

Thermoset materials, in particular, offer much more heat resistance than thermoplastics. As a result, you combine both heat resistance and exceptional strength through the injection molding process.

Our Precision Plastic Fabrication Services

In addition to injection molding, we offer a wide range of other custom plastic fabrication services. Our engineering team consists of many industry experts, so we can complete even the most challenging, high-volume projects with ease.

We can also help you find the best method to create your products. You will always receive the parts that are built to your exact specifications.

Our services include Thermoplastic Injection molding, prototype molding, engraving, CNC machining, post-mold molding, secondary operations, hardware insertion, hot stamping, silk screening, screen printing, assembly, ultrasonic welding, plastic welding, and injection molding tooling.

Why Choose Jaco Over Other Injection Molding Companies?

Many clients who seek out services from Jaco Products were previously turned down by other injection molding companies. Here at Jaco, we never say, “It cannot be done.” We will use all the tools, knowledge, and materials at our disposal to find an optimal, cost-effective solution for your project. In fact, we can even complete projects in cases where the product cannot be molded with the existing design, materials, or close tolerance requirements.

Jaco Products sets itself apart from other injection molding companies with unmatched expertise, innovative fabrication techniques, and high-quality products. With our immense experience in custom plastic manufacturing, our team is always prepared to discuss the design and material requirements for your next project.