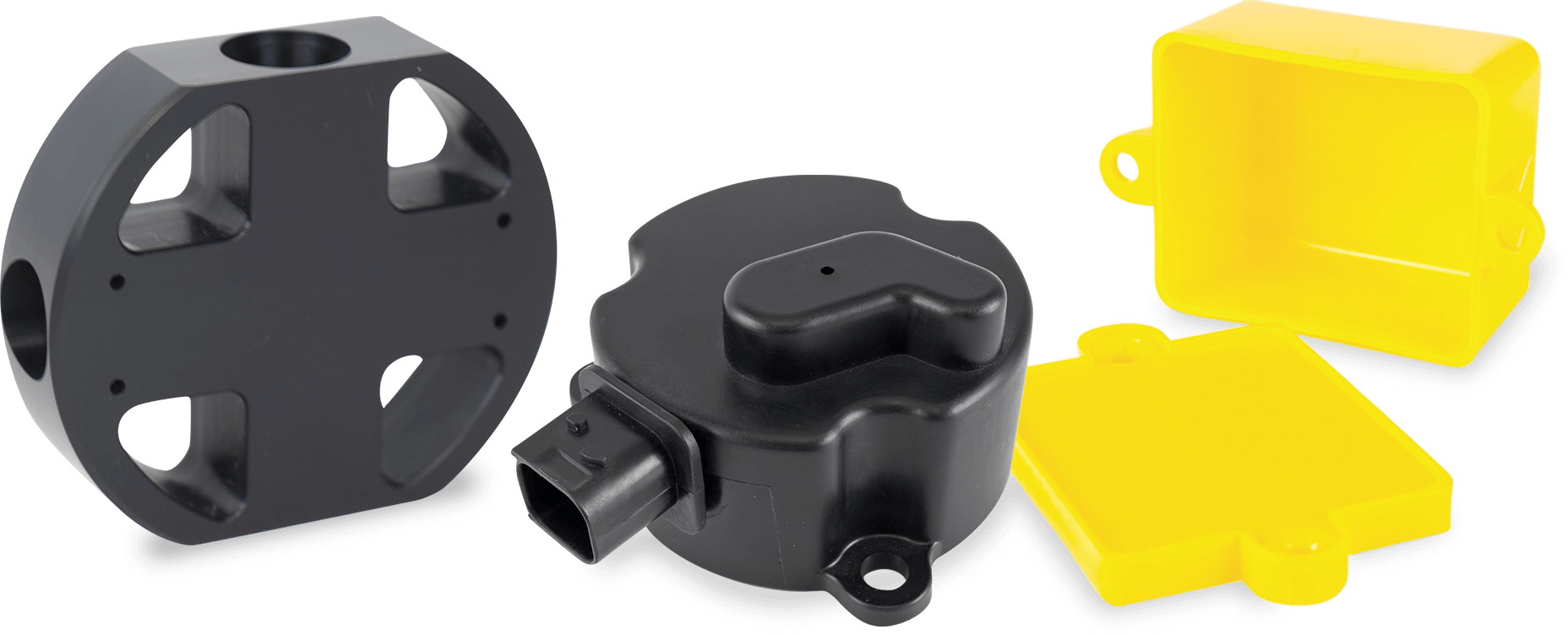

Custom Injection Molding Services

Jaco Molding Products offers custom injection molding of thermoplastic materials up to 29 oz. Our reputation for injection mold technology establishes Jaco Products as experts in production and precision plastic injection molding services and parts at a competitive price.

Our technical staff is experienced in all aspects of the injection mold engineering process and is capable of producing quality plastic injection molded parts because they understand each and every aspect of the plastic injection molding process. We are one of the premier injection molding companies. When others say “No Quote,” it’s a job for Jaco.

Plastic Injection Molding Service

At Jaco Products we specialize in producing high-quality plastic injection molded parts and mold tools. Our processes are in-house to provide full production-quality CNC machining services to make tools from a variety of materials and can produce small or large lots in a wide variety of resins.

Using advanced raw material verification and quality assurance, we excel at making tools, material distribution, and finished parts to exceed your expectations. If you’re ready to start your next project, give Jaco Products a call today.

Know Your Injection Molding Raw Materials

Virtually any type of thermoforming resin can be used in the injection molding process, and there are thousands of kinds to choose from in order to achieve just about any performance that you need for your project. Check out our list of frequently used materials:

How Injection Molding Works

Plastic injection molding is the industry standard for producing large volumes of finished plastic parts for commercial and industrial uses. Injection molding is the process of injecting melt liquid under high pressure into the cavity of a metal die and then getting rapidly cooled, forming a solid shape. A single cycle to make a finished part may take anywhere from a few seconds to minutes depending on part complexity and size.

Request a Quote

Plastic Materials We Work With

Jaco specializes in molding:

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal; Celcon, Delrin

- Polyamide: Nylon 6/6; Zytel

- Polyamide: Nylon 6/6, glass filled LGF nylon

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Polycarbonate (PP) Lexan, Makrolon

- Polycarbonate/ABS Alloy

- Polyetherimide: Ultem injection molding

- Polyetherimide, fiber reinforced; Ultem

- Polybutylene Terephthalate; Valox, Crastin

- Polypropylene: Maxxam, Profax

- Polystyrene: Styron

- High-Impact Polystyrene: HIPS

- Thermoplastic Elastomer: Isoplast, Santoprene Acrylic; Plexiglass, Acrylite

Custom Engineered Molded Electrical Insulator Products

NEMA STD and UL Approved

One of Jaco’s unique injection molding capabilities is our ability to mold high-temperature materials, such as Ultem and Polysulfone. As a NEMA STD and UL Approved supplier to the electrical insulation market, Jaco’s staff is unparalleled in their knowledge of insulator materials, the plastic injection molding process, and electrical insulator design. From the most intricate parts to the tightest tolerances and specifications, we can provide expert insight, no matter the project.

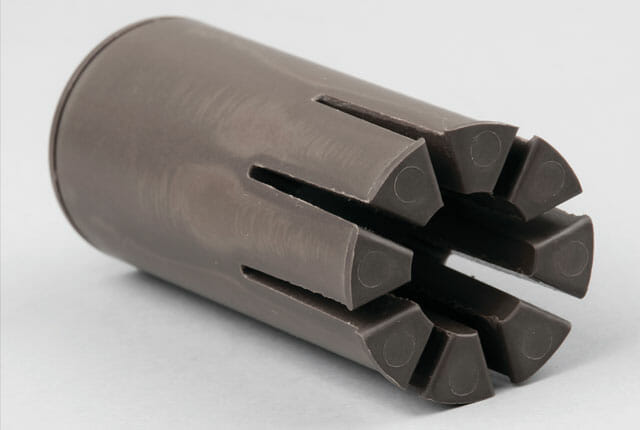

Plastic Injection Molding Molds

Jaco personnel perform minor repairs of our injection molding tooling in house. Local mold builders, who meet our suppliers’ qualifications, design and build our custom plastic injection molds. We follow the Society of Plastic Industry (SPI) industry practices regarding maintenance and mold ownership for custom injection molding. This detail-oriented process means every product we create is of the highest quality.